We Spark Productivity

Our industry-unique solutions are designed to make injection molding easier for all molders!

From simple to complex, we open processing windows, maximize uptime, and enable advanced manufacturing practices.

Contact us today to see how we can Spark Productivity for you.

Hot Runner Controllers

MOD24® COMING SOON! A modern, modular controller with plug-n-play expansion up to 192 zones.

Pulse™ for up to 180 zones. Advanced I/O, max % power control w/ 10″ HMI.

Hot Runner Maintenance

Instantly diagnose circuitry on hot runner systems and cables using our patented MoldXChecker®

and CableXChecker® devices.

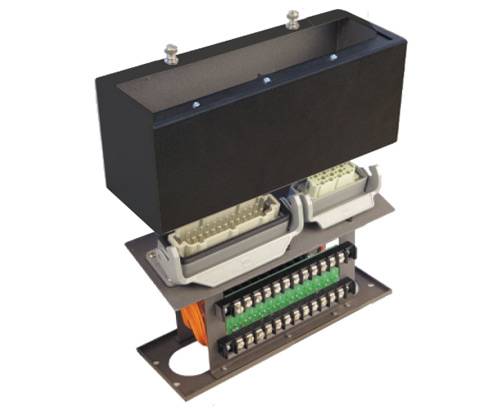

Mold Boxes

The SmartMold™ Hot Runner Mold Box saves time and money by protecting thermocouples and control modules while offering ease of access to connectors. Custom mold boxes are available.

Hot Runner Cables

Standard and custom heater and thermocouple cables using machined silver pins, heavy-duty strain reliefs, and shielded cable.

What is Advanced Hot Runner Temperature Control?

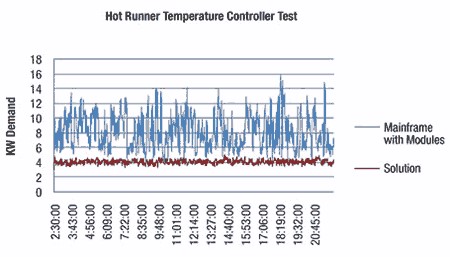

Hot runner systems replace cold runners that connect individual parts of a multi-cavity tool, reducing scrap, cycle time, part handling, and in some cases allowing for more intricate molding. The key to hot runner temperature control is introducing the least amount of temperature variation into the system, regardless of set point. We can see the difference in our Fast Heat control vs. other controllers by the peaks and valleys of KW demand from turning heaters on and off. You also notice our KW demand baseline is much lower. This is the difference between older technologies that only control one module at a time vs. our control that manages all zones as a complete system while predicting temperature behavior. Molders benefit from larger processing windows and energy savings.

How Fast is Fast Heat?

Thermocouple readings are measured SIX times every .0694 seconds for every zone!

% power is updated for every zone once every .4167 seconds!

A “Pulse” of power is only .0083 seconds long!

Now that is FAST! This is one of the secrets to precise temperature control (we can’t share them all). The results are larger processing windows, less scrap, and the confidence to mold challenging parts.

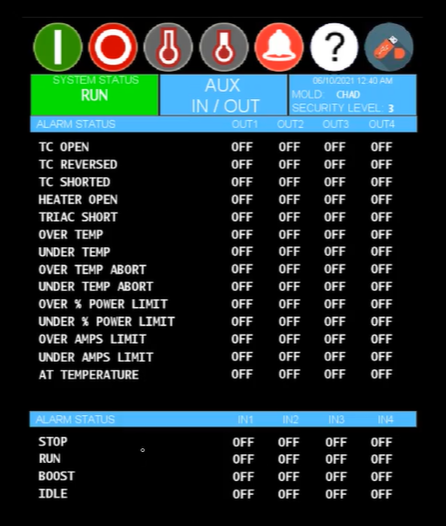

Pulse Auxiliary I/O Applications

- % Power Alarm – turn off a zone, the controller or stop the injection molding machine.

- Temp Alarms – change conveyor direction toward an inspection bin.

- Boost – increase injection pressure can automatically boost tip temps or use for preheat stations to raise temps before shuttling.

- Idle – automatically lower temps during production interruptions.

- Soak Timer – give the injection molding machine the all-clear to inject.

- And more…

Latest News and Best Practices

Find out all the announcements, techniques and events we are offering.

Hot Runner Productivity Series

Hot Runner Productivity Series Register for special pricing, tools, and training to help with hot

Hot Runner Injection Molding Process

Injection Molding Process and Hot Runner Systems Processing injection molds used to be considered a black art.

Hot Runner Troubleshooting

Hot Runner Troubleshooting First, Staying Out of Trouble MoldMaking Technology® and Plastics Technology magazines published articles about