Hot runner energy savings are not just about reducing total power usage. It’s about minimizing peak demand, which often drives the highest utility costs in manufacturing facilities.

The Pulse Hot Runner Controller™ reduces peak kilowatt demand using three core strategies that work automatically in the background.

The first strategy is Even Soak™ startup. Instead of energizing all zones at once, the controller sequentially heats defined groups from cold to setpoint. This significantly reduces the initial amperage spike that occurs during startup and protects the tool from uneven thermal expansion.

The second strategy is to limit the percent power. Each zone can be governed to a maximum power level during ramp-up and production. This prevents heaters from drawing excessive amperage and allows larger tools to run on limited electrical service without tripping breakers.

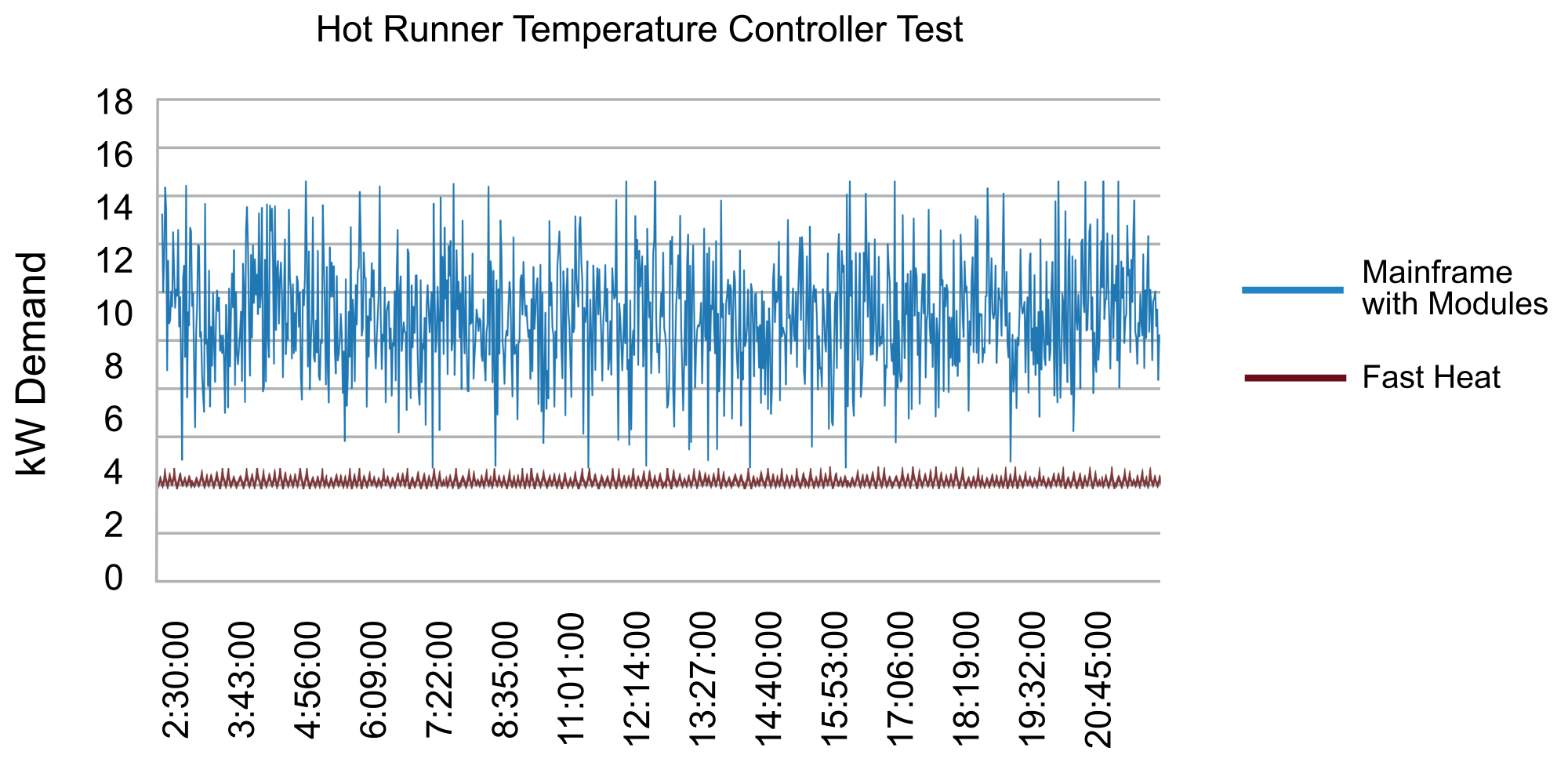

The third strategy is Waterfall Technology™. During steady production, the controller staggers the heater on and off cycles so that zones do not overlap unnecessarily. This smooths amperage demand across the system and minimizes electrical volatility.

In addition to lowering energy costs, these methods improve temperature stability. Reduced power cycling leads to more consistent heater output and easier process control. Operators experience fewer temperature swings and improved part quality.

By combining startup sequencing, power governance, and intelligent heater cycling, the Pulse controller delivers measurable hot runner energy savings without sacrificing performance.

FAQs

What causes high peak energy costs in hot runner systems?

Simultaneous heater startup and overlapping power demand.

How does Even Soak™ reduce energy usage?

It prevents all zones from drawing maximum power simultaneously.

Does limiting the percent power affect performance?

It slightly increases warm-up time but improves stability and prevents overloads.

What is Waterfall Technology™?

A method that staggers heater cycling to reduce overlapping power demand.

Does energy optimization improve temperature control?

Yes. It reduces volatility and improves consistency.