Heated Machine Nozzles for Injection Molding

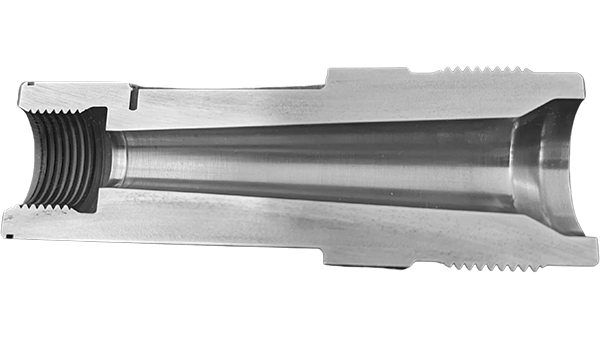

Heated Machine Nozzle With Continuous Tapered I.D.

- Stainless PM (particle metal) Tool Steel Machine Nozzle with Continuous Taper I.D.

- ZROC™ (Zeiger Release Optical Clarity) metallurgy is optimized for clear part production such as Polycarbonate (PC) and Acrylic (PMMA)

- ZHCW20™ option for maximum corrosion and good wear resistance. Alleviates sulfidation associated with processing sulfone polymers.

- ZHWC9™ for maximum wear resistance to glass filled resins and good corrosion resistance

- Ideal for Halogen Free Fire Retardants (HFFR), flexible and rigid Polyvinyl Chloride (PVC), frequent color changes or general purpose molding.

- Self-cleaning (eliminates black specs)

- Less shear (eliminates bubbles and streaking)

- Use with any size injection molding machine

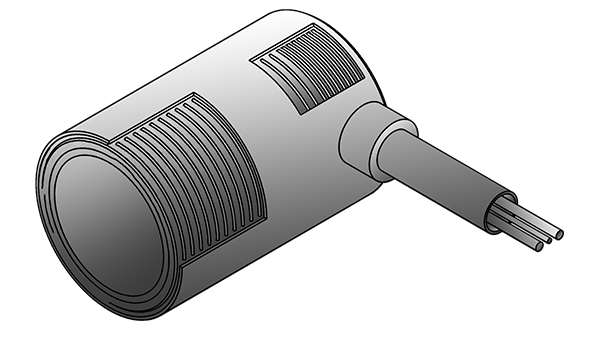

- Swaged, Stainless Sleeve Heater with Replaceable Thermocouple

- Maximum heat transfer and uniformity

- Precision CNC wound, high surface area heating element

- Three thermocouple locations at 120 degrees

- Long lasting

- Optional 45 degree lead toward the tip

- 4.25”, 5.25”, 6.25”, 7.25” Standard Lengths

- Customizable

References for Heated Machine Nozzle:

- About Zeiger Industries

- Design Origin

- Plastics Technology Magazine Article

- Plastics Machinery Magazine Article

- 3rd Party Support for Fully Tapered Machine Nozzle – Article in Plastics Technology

Zeiger and Spark Industries have collaborated on a new heated tapered nozzle that’s designed for reduced pressure drop, self-cleaning operation and the ability to work with aggressive materials, including polysulfones and halogen-free flame retardants (HFFR). Zeiger’s Stan Glover told Plastics Technology that the nozzles, which launched at the PTXPO (March 28-30; Donald E. Stephens Convention Center; Rosemont, Ill.), are available for any and all injection molding machine brands and sizes, with a sweet spot within small- to mid-tonnage machines up to about 300 tons. The general screw diameter range the heated tapered nozzles can work with is 16 to 70 mm.

Promising maximum heat transfer and uniformity, the nozzle’s heating component, which slides over the body, is constructed from swaged stainless steel, with heating from a precision-wound, high-surface-area heating element wire featuring a replaceable thermocouple. The nozzle body is constructed from hardened PM stainless tool steel and its melt channel features a continuous taper. This design allows for self cleaning and more rapid color changes.

The design and construction materials lend the nozzle to use with polycarbonates, where it can help minimize specks and streaking, as well as sulfone resins, where its 20% chromium content alleviates sulphidation. It’s also suited for use with resins that feature HFFR additives.