Injection Molding Best Practices:

What’s All The Hubbub?

In short, best practices are sets of methods and techniques that increase efficiency and develop structured processes with optimal results. Best Practices allow you to streamline procedures and stick to industry standards.

Fast Heat by Spark Industries assists those in the plastic industry in setting up their business for success by following Injection Molding Best Practices and by sharing how you can improve your company’s best practices.

Of course, since you’re here, you probably already know Fast Heat is all about optimizing hot runner injection molding best practices and processes with the utilization of their custom products.

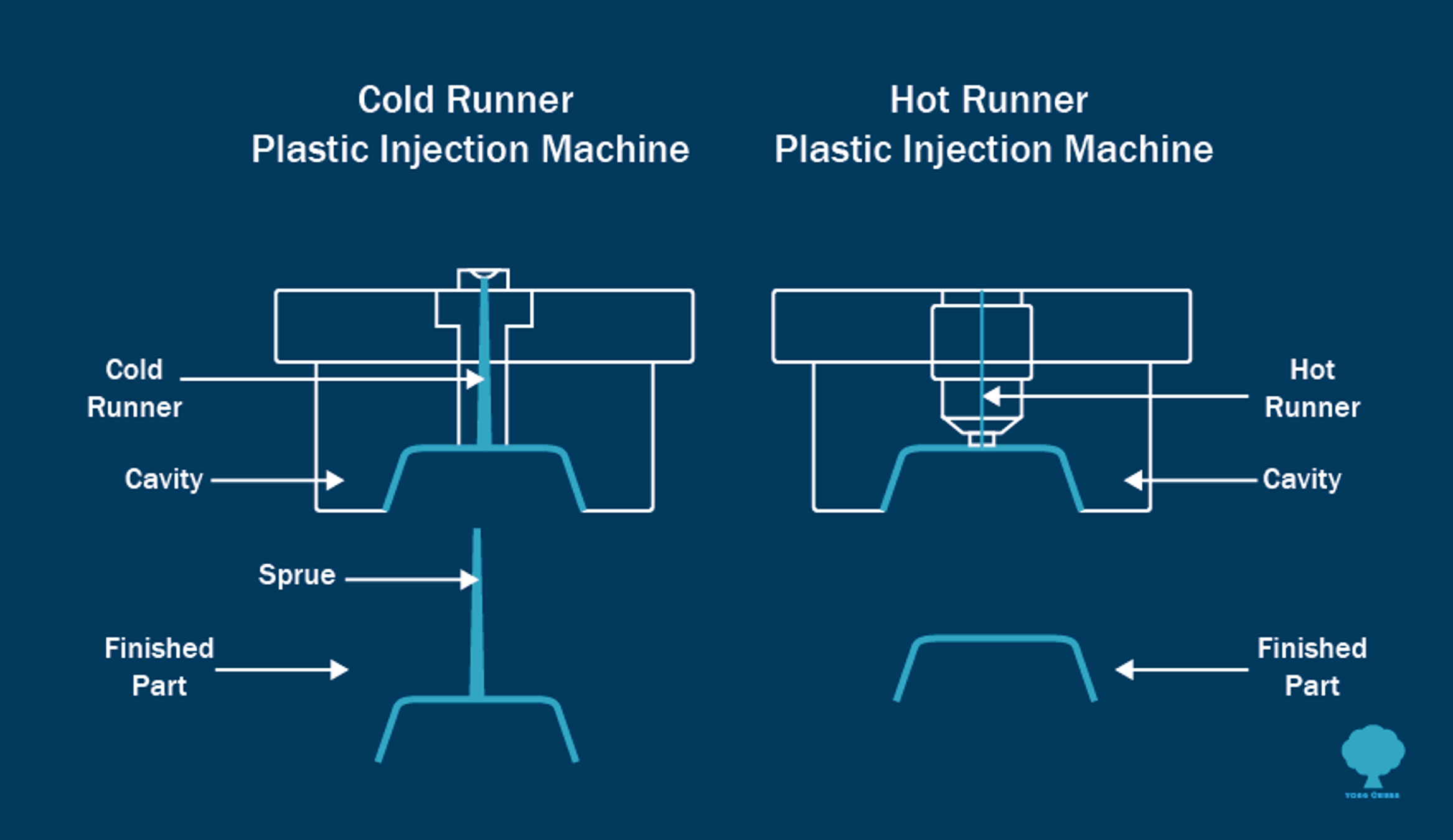

However, just in case you’re new to the world of hot runner applications or injection molding, let’s just start off with a little basic review to get you in the zone:

To start, take a look at this Plastics Technology article that gives a succinct explanation of what a hot runner system is:

First, think of it as an extension of the molding machine itself. Its purpose is to keep the plastic molten at a proper temperature on its path to the cavity. So basically, it’s just a piece of heated steel with a round channel in it for the melt to flow through. Ideally, this channel would be running at the exact temperature on the controller, free of obstacles such as dead spots or components that could create hangups and cause scrap issues with color changes or contamination.

You can check out the full article in PT addressing hot-runner benefits, improvements, and everyday issues from the perspective of decades of experience, A View from the Bottom Up.

After you have examined these standpoints, pop over to peruse how Fast Heat by Spark Industries Hot Runner Controllers will help you achieve the consistency you need.

Another area of importance touched on by PT is heated sprue bushings and how they contribute to a uniform heat profile:

Switching from a Cold Sprue Bushing to a Heated Sprue Bushing

We know there’s really a lot of information out there. Who knew!? But, now you can make an informed decision. Examine Fast Heat’s offerings here and make your choice of Heated Sprue Bushings.

“Hold up,” you say, “not so fast.”

What, not quite ready to pick out controllers, sprue bushings, and Mold Boxes? Do you want to know more? Ok, you know what hot runners do…but why would you want to choose a hot runner mold in the first place…what does it mean for you and your business? No worries, we’re here with more substantiating info:

Top 5 Benefits of Hot Runner Systems:

- Allow a wider range of resin application

- Mold more complicated and detailed parts

- Higher throughput

- Lower labor costs

- Reduce scrap

You may also want to check out this article, “Seven Key Advantages of Hot Runner Systems”, by JOHN THIRLWELL, VP OF SALES AND MARKETING, CACO PACIFIC CORP., PUBLISHED IN MOLD MAKING TECHNOLOGY, where, among other advantages, melt flow…one of our favorites, is discussed.

Balanced Melt Flow

The flow advantage that hot runners have is that the melt channels are in separate, externally heated manifolds, which are insulated from the surrounding mold plates. Different from a cold runner plate, the hot manifold can be designed to have flow channels on multiple levels to ensure that the resin flows the same length from the molding machine nozzle to each cavity with the same channel profiles and diameters, number of turns, heat soak and pressure loss (see Figure 1). In other words, the plastic reaches each cavity – whether there are two or 96 – with the same pressure and thermal history. This designed-in temperature and pressure control is particularly favorable for resins that have narrow processing windows.

Figure 1: Balanced melt flow – a multi-level hot manifold gives equal flow and pressures to all cavities for equal filling

Now, you’ve read the experts’ views, and you’re finally convinced that you have some projects that make sense to convert over to hot runners. But you may also be asking yourself, “How am I going to accomplish this?” Once again, we look to the experts at Mold Making Technology, who provide a helpful summary on:

How to Transition from a Cold to Hot Runner Mold

Moldmakers and molders who use hot runner systems in their molds will be the first to disclose that it is often the most expensive part of the mold build. But they quickly add that it is worth the investment based on reduced cycle time, resin cost, elimination of post-processing, product lifecycle, etc.

Finally! You have your hot runner mold projects in place! Ok, we know it isn’t quite as easy as that…it will be a process…but once you do get your projects transitioned, you will want to know more about what Fast Heat can do for you. How are you going to benefit from Fast Heat by Spark Industries once you have decided to go with a hot runner tool?

Our Best Practices blogs will help answer how Fast Heat by Spark Industries will be of value, and you can check them out in their entirety with the provided links. We have also included some useful connections directly to our product pages. Of course, you can always CONTACT US with any specific questions.

Highlighting Injection Molding Best Practices | Fast Heat by Spark Industries

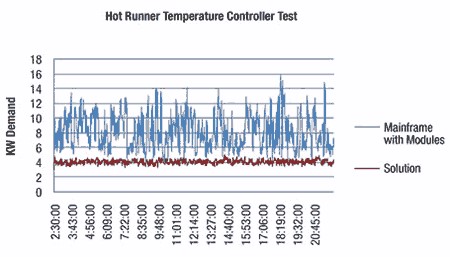

Hot Runner Temperature Controllers Boost Productivity and Quality

This may seem like stating the obvious, but if you can cover or “control” variables from nozzle to cavity, you are definitely reducing the likelihood of problems with your parts and everything in between. Mold manufacturers that install a quality temperature controller on a hot runner system will not only lengthen a mold’s life but will help improve part quality…it’s just that simple.

Fast Heat by Spark Industries will increase your efficiency and, ultimately, your bottom line.

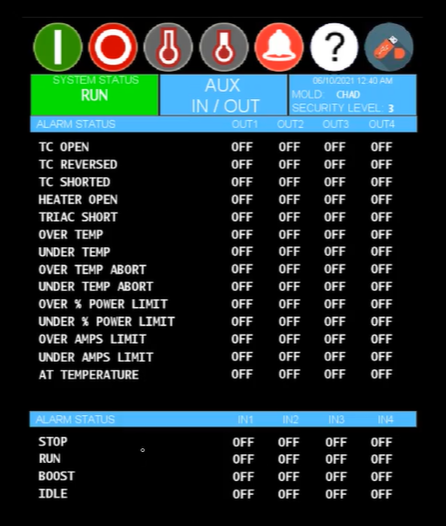

Additionally, you can read about the Pulse Hot Runner Controller Pulse™ Hot Runner Controller and its related alarms in a troubleshooting menagerie that introduces some concepts such as “bake out” and why you need to address it in Troubleshooting.

Hot Runner Performance

Hot Runner performance is critical to maintaining production schedules and eliminating costly downtime.. Having the tools to ensure your hot runner performance is peak is where Spark Industries comes in.

Manny Diaz developed the MoldXChecker® as a result of feedback from customers who stated they would like to be able to test the hot half and the associated elements more quickly. Also, for obvious reasons, they would like less experienced employees to be able to manage the task without extensive training. Save time; save cash!

Manny Diaz, Managing Partner of Fast Heat by Spark Industries, and inventor of the CableXChecker® , was constantly running into the issue of showing up at companies to do maintenance and having no available cables to use to troubleshoot the hot half of the mold; the cables that were known to be good where always already in use on the floor.

And to avoid those Cable Connection Problems from the get-go:

You can accomplish some quick fixes… and one significant change with great results is to include 24-pin male and female connectors; unlike your 25-pin connectors, these 24-pin connect ors are heavy-duty. The pins won’t bend or get pushed back and are rated for 16 amps. They also have screw terminations and are much easier to connect to mating mold boxes, cables, or controllers. Take a look at the original article for a detailed diagram of the Anatomy of a Connector MoldMaking Technology Article and further tips.

ors are heavy-duty. The pins won’t bend or get pushed back and are rated for 16 amps. They also have screw terminations and are much easier to connect to mating mold boxes, cables, or controllers. Take a look at the original article for a detailed diagram of the Anatomy of a Connector MoldMaking Technology Article and further tips.

Fast Heat by Spark Industries has answers for all of your hot runner controller and hot runner cable needs. Make us your go-to guys. We are here for all your questions; it’s what we do!

The last Fast Heat item we want to share with you today is regarding screw tip assemblies. Material and Design are key elements of consideration, and there really aren’t any BAD tips, per se. But you have to figure out what tip is best for your specific job. What resins are you running? What material is your tip going to be made of, and what type of design is going to benefit you most? Fast Heat can help! There are literally hundreds of options out there from which you can choose, but we encourage you to take a look at these manufactured by Zeiger Industries, Screw-Tip Assemblies.

Here at Fast Heat, we look at publications like Plastics Technology and Mold Making Technology for guidance in all things plastic. We want to add one other PT piece we think you may find valuable, Tips to Help You Succeed with Hot Runners. Having said that, we have thrown a lot of information at you, and we had you roaming cyberspace to and fro…but, in the end, we think you will agree that Fast Heat by Spark Industries is also a great resource. For all things related to Injection Molding Best Practices, we want to be your 1st Resource!

Check Out Our Productivity Series!

- Processing with Hot Runners – https://fastheatbyspark.com/

hot-runner-injection-molding- process/ - Electrical Consumption of Hot Runners – https://fastheatbyspark.com/

hot-runner-kw-demand/ - Troubleshooting Hot Runners – https://fastheatbyspark.com/

hot-runner-troubleshooting/ - Hot Runner Maintenance https://fastheatbyspark.com/

hot-runner-maintenance-guide/ - Injection Molding Cell Integration of Hot Runners – https://fastheatbyspark.com/

hot-runner-control-input-and- output-communication/