Cables and Connectors Program

The smallest items such as mold power cables, thermocouple cables, connectors, and pins can have an impact on the overall performance of your temperature controllers, molds and production work cell. Fast Heat will refurbish your non-working pile of cables and connectors into the “like new” condition you can count on once again—while saving you a pile of money!

Cables, Mold Connectors, I/O Connectors and Mold Boxes

- Inspect existing equipment. Replace components as needed.

- Pins missing/pushed back and repair where necessary.

- Hood side pins broken/missing.

- Latches off, missing or broken.

- Pins missing or pushed back.

- Mold box bent and/or not closing properly.

Related Links –

- MoldMaking Technology Magazine – The Ins and Outs of Hot Runner Temperature Control

- Hot Runner Cable Connector Anatomy

- Common Hot Runner Cable Connection Problems

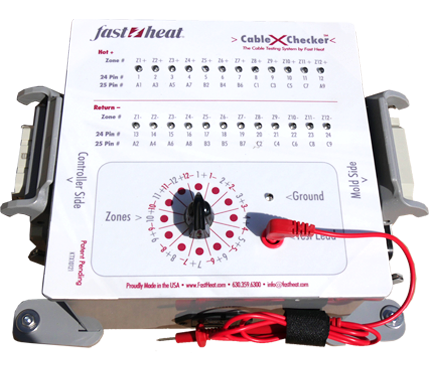

- CableXChecker®

- Hot Runner Maintenance

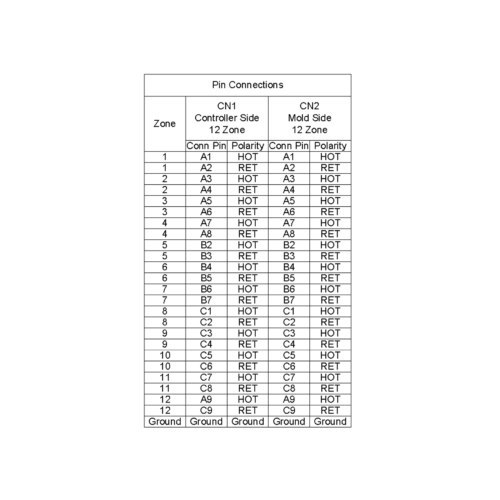

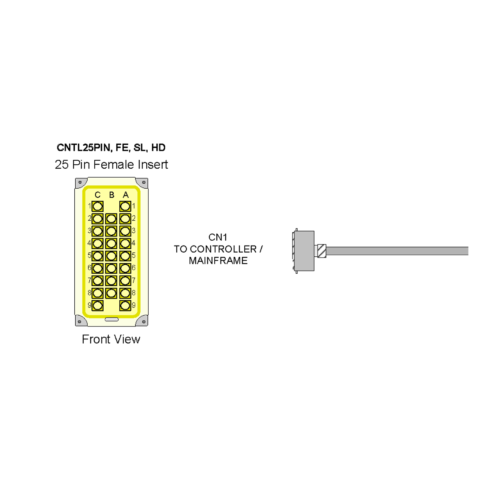

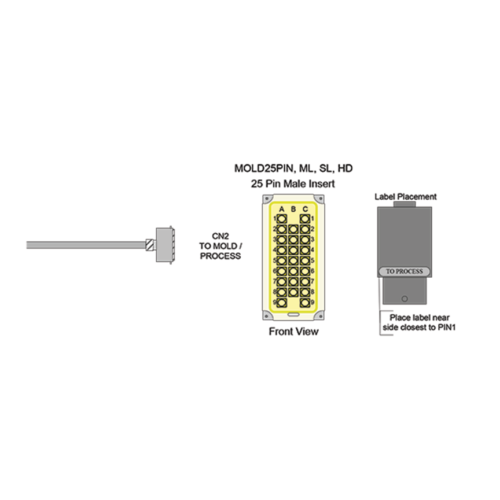

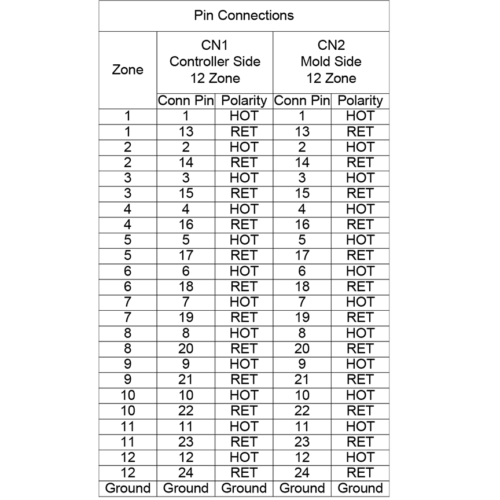

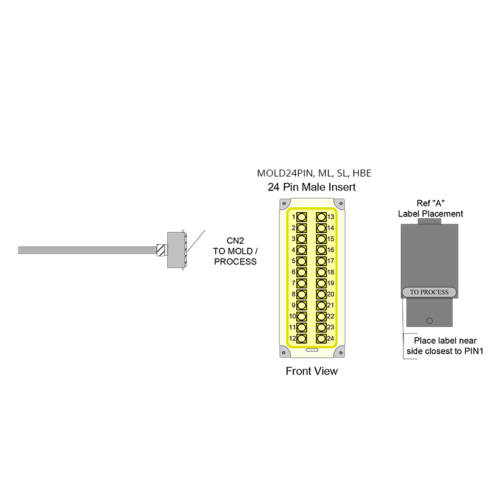

We strongly encourage molders to use the 24-pin, machined, and molded male and female connectors shown above. Unfortunately, a lot of molders are stuck with old industry standards that utilize 25-pin connectors. The pins are very delicate (1/16-inch diameter exposed) and can easily be bent or pushed back when being mated to a female connector on a mold box, cable, or hot runner controller. The same thing can happen with the female inserts because the metal inserts are only press-fit into the connector. These 25-pin connectors are also only rated for 10 amps, yet many shops use them for hot runner heaters that can easily exceed 15 amps.

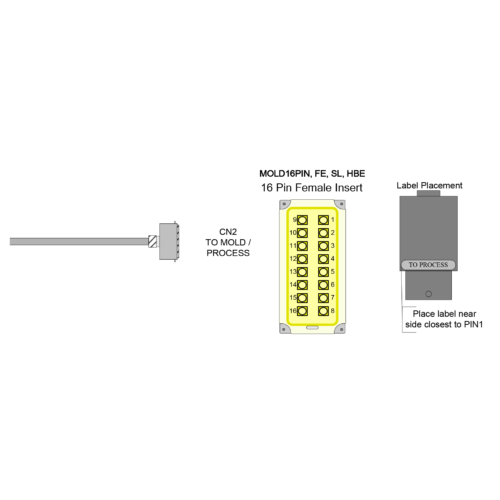

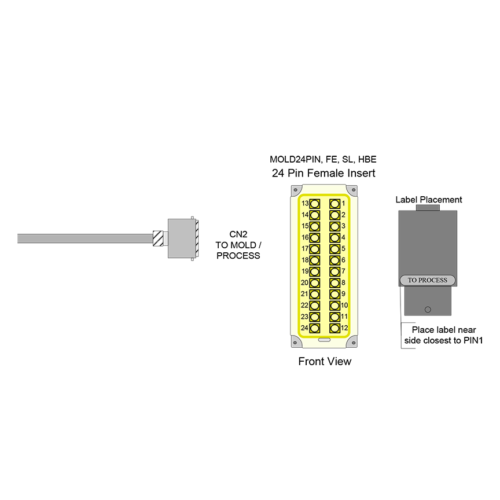

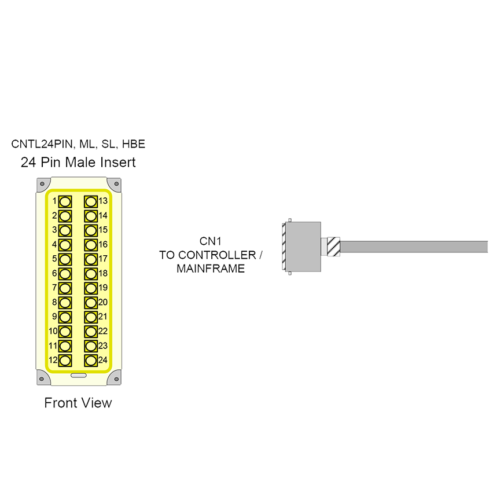

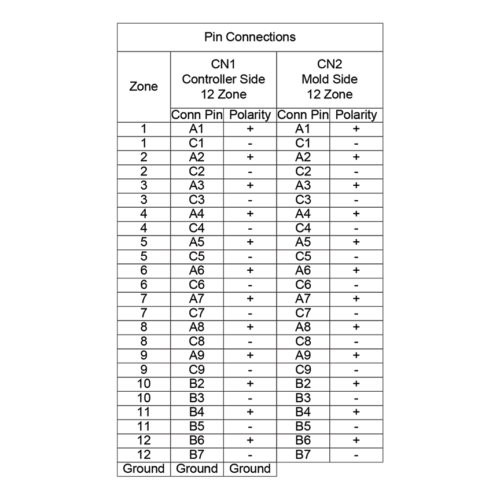

Spark recommends using 24-pin hot runner connectors as shown here

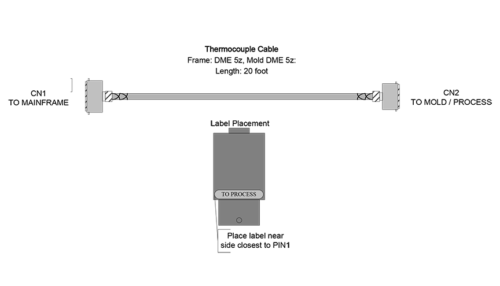

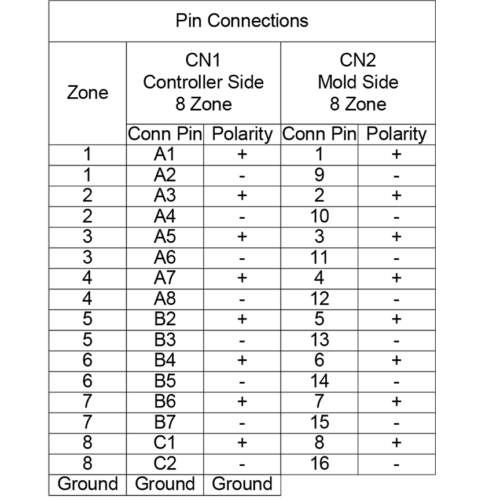

Hot Runner Cables - Combo Heater and Thermocouple