Pulse™ Hot Runner Controllers

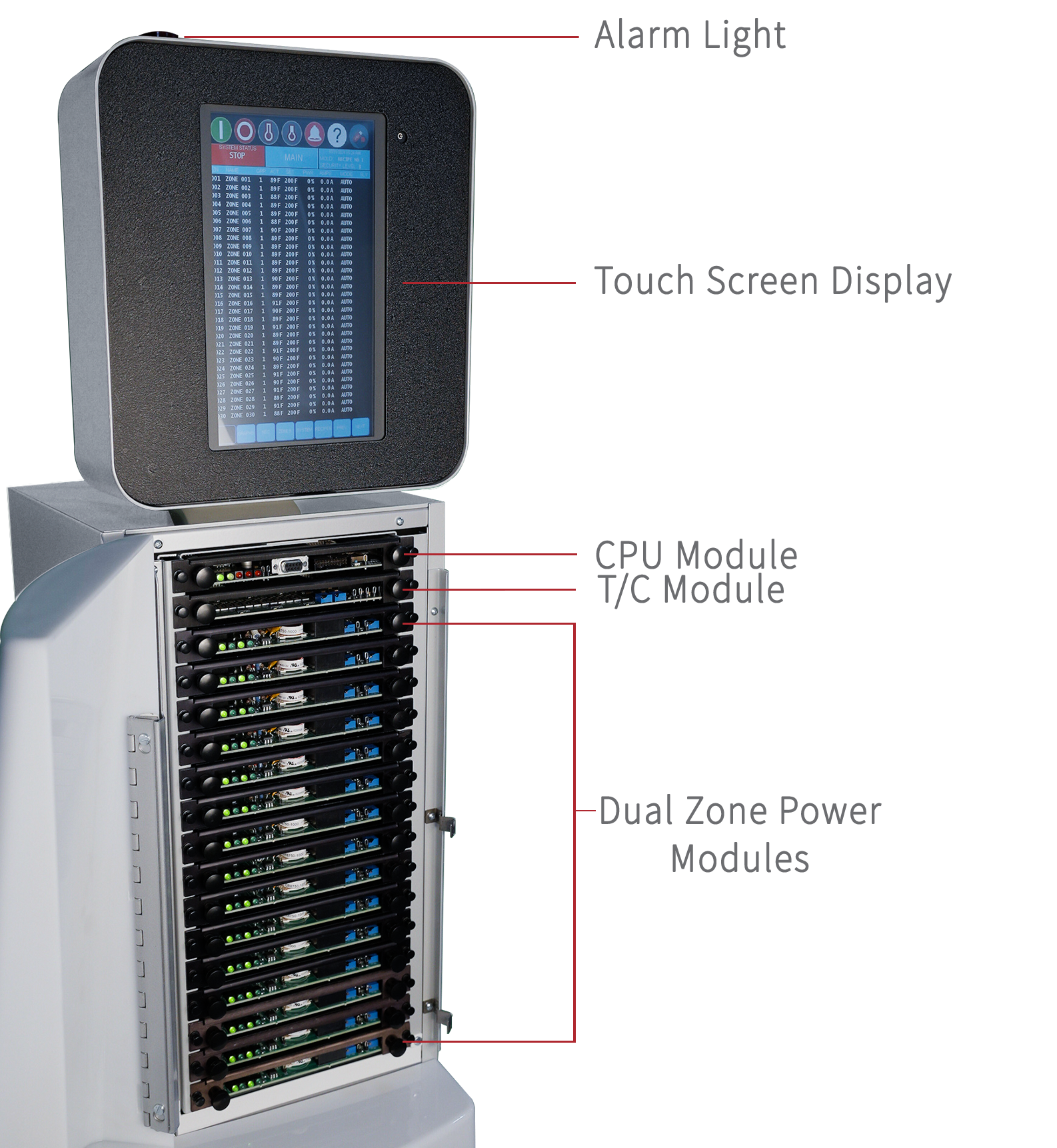

- Configurations of 30-zone capacity cabinets up to 180-zones.

- Optional I/O for integration with the injection molding machine and other equipment

- 10.1″ LCD, 1024 x 600 resolution touchscreen HMI w/ ethernet for VNC Viewer and USB for saving screenshots

- Compact footprint

- Remote mount display option

- 240V w/ integrated transformer up to 45 KVA

Fast Heat Pulse Hot Runner Controllers

- Customer Specified Connectors

- Moisture Bake-Out

- Evensoak (zone managed sequential start-up)

- Update Zones by Group

- Slave Zones Automatically or Manually

- Store up to 50 Recipes

- 3-Level Customizable Security Codes

- Constant Tuning PID Algorithm

- Max % Power Control/Alarm (able to use lower amp service and detect leaks)

- Instant Diagnostics

- Active Thermocouple Protection*

- Energy Saving Waterfall Technology (minimizes peak KWh and amp draw)

- 4-Channel I/O for Softsoak & Alarm Outputs and Inputs for Run, Stop, Boost, Idle. Learn More>

- 10″ LCD HMI w/ VNC Viewer

- 240V 3-Phase.

- Options – Remote Mount Display Cable, 15 or 45 kVA Integrated Transformers

Why Choose Pulse Hot Runner Controllers?

There has been a trend over the last decade to integrate hot runner temperature controls into injection molding machines. While this may seem like a good idea, molders are sacrificing a lot of value that comes with a specialized hot runner temperature control like our Fast Heat Pulse controller. Our temperature controller is also a valuable tool for other applications such as extrusion, compression molding and any application with simplicity, precise control and work-cell integration are important.

| Pulse vs Other Integrated Controls | Pulse | Others |

|---|---|---|

| Easily Expandable w/ 30-Zone Cabinets | Yes | No |

| 4-Channel I/O Automation – Soak Timer, Alarms, Run/Stop/Boost/Idle | Yes | No |

| Waterfall Technology Power Mgt (min peak KW demand) | Yes | No |

| Max % Power Limit (enables lower amp service) | Yes | No |

| Active Thermocouple Protection | Yes | No |

| Table-Top MoldXChecker Optional | Yes | No |

| Tabular 30-Zone View and Mgt by Group | Yes | No |

| Embedded Firmware (no hard drive) | Yes | Some |

| Instant Diagnostics | Yes | Most |

| Multi-Level Security | Yes | Most |

| LCD Touchscreen w/ VNC Viewer (Ethernet) | Yes | Most |

| Recipe Storage | Yes | Yes |

| Zone Slaving (Auto and Manual) | Yes | Yes |

| Evensoak Sequential Group Start-Up | Yes | Yes |

| Moisture Bake-Out | Yes | Yes |

A positive temperature coefficient (PTC) device allows the amount of current generated during the normal operation of a thermocouple to flow through but shuts down when the current flowing through becomes too high. Unlike conventional fuses, the PTC resets itself when the current drops to a normal level. The time it takes to trip the device (time-to-trip) depends on the current and falls rapidly as the current increases.

Line Up

Pulse 30™

Pulse 60™

Pulse 120™

Pulse 180™

| Specifications | Pulse 30 | Pulse 60 | Pulse 120 | Pulse 180 | |

|---|---|---|---|---|---|

| Heater and T/C Cable Length |

20′ or custom | 20′ or custom | 20′ or custom | 20′ or custom | |

| Outside Dimensions Overall (W”xD”xH”) |

22x26x67 | 22x26x67 | 33x26x67 | 44x26x67 | |

| Maximum Number of Zones |

30 | 60 | 90 or 120 | 150 or 180 | |

| Card Slots | 15 | 30 | 45 or 60 | 75 or 90 | |

| Display w/ Ethernet VNC Viewer |

10″ Color Touchscreen |

10″ Color Touchscreen |

10″ Color Touchscreen |

10″ Color Touchscreen |

|

| Recipe Storage | 50 | 50 | 50 | 50 | |

| 240V, 3-Phase w/ Optional Transformers |

15 or 45 kVA | 45 kVA | Engineering Required |

Engineering Required |

|

| 4-Channel In/Out Input / Output |

Optional | Optional | Optional | Optional | |

| Remote Mount Display Cable |

Optional | Optional | Optional | Optional |

Related links:

- Plastics Machinery & Manufacturing Magazine – HMI Remote Monitoring and Control

- MoldMaking Technology Magazine Feature

- Plastics Technology Magazine Feature

- Maple Systems HMI Featured Case Study

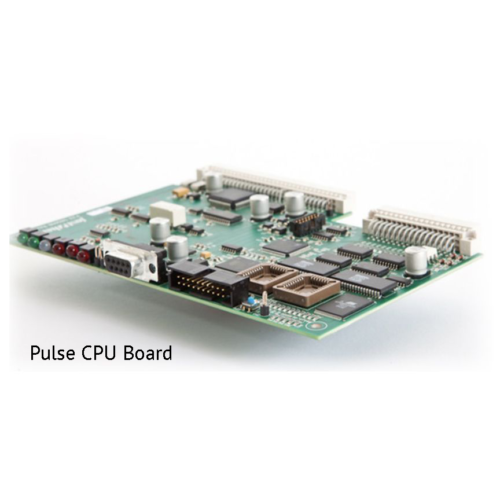

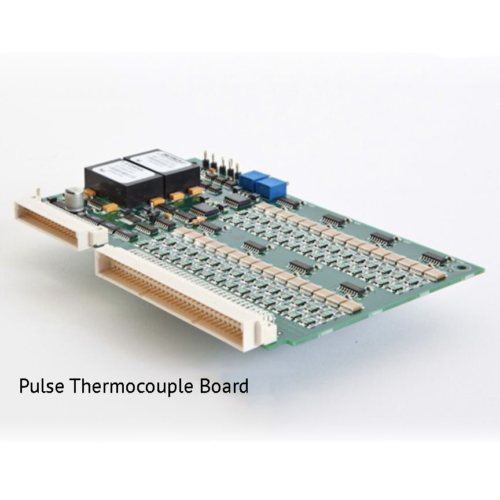

Pulse Hot Runner Controller Spare Parts