Hot Runner Control Input-Output Signals

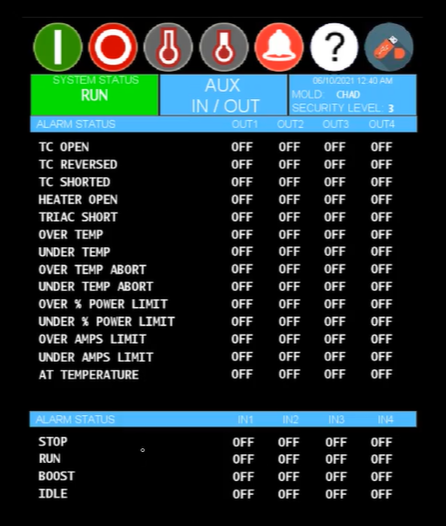

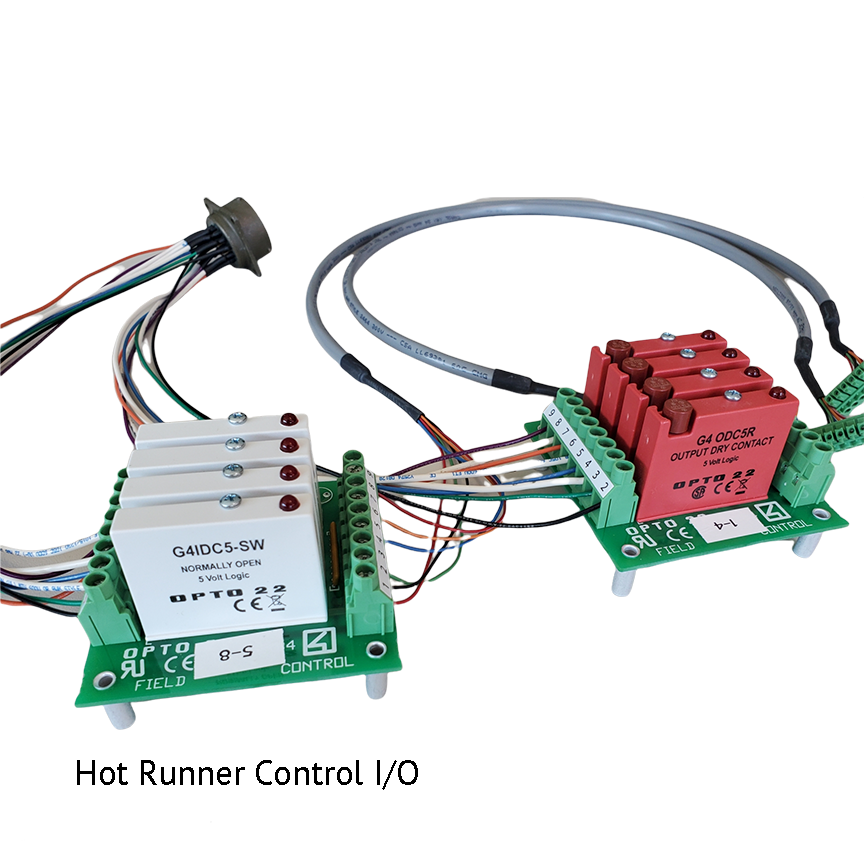

Hot runner control input-output signals are a terrific way to integrate hot runner temperature controls with injection molding machines. Further, they can be tied in with robots, conveyors, or other peripheral equipment. The Fast Heat Pulse Controller has four INPUT and OUTPUT channels. The channels are configurable per order, but the INPUT is typically a N/O (normally open) dry contact or a 10-32 DC voltage signal. And, the OUTPUT standard is a N/O (normally open) dry contact. Each OUTPUT channel can have one or more ALARM STATUS or an AT TEMPERATURE notification assigned to activate it. Each INPUT channel is typically assigned to either RUN, STOP, BOOST, or IDLE.

Hot runner control input-output signals are a terrific way to integrate hot runner temperature controls with injection molding machines. Further, they can be tied in with robots, conveyors, or other peripheral equipment. The Fast Heat Pulse Controller has four INPUT and OUTPUT channels. The channels are configurable per order, but the INPUT is typically a N/O (normally open) dry contact or a 10-32 DC voltage signal. And, the OUTPUT standard is a N/O (normally open) dry contact. Each OUTPUT channel can have one or more ALARM STATUS or an AT TEMPERATURE notification assigned to activate it. Each INPUT channel is typically assigned to either RUN, STOP, BOOST, or IDLE.

Example use cases include but are not limited to:

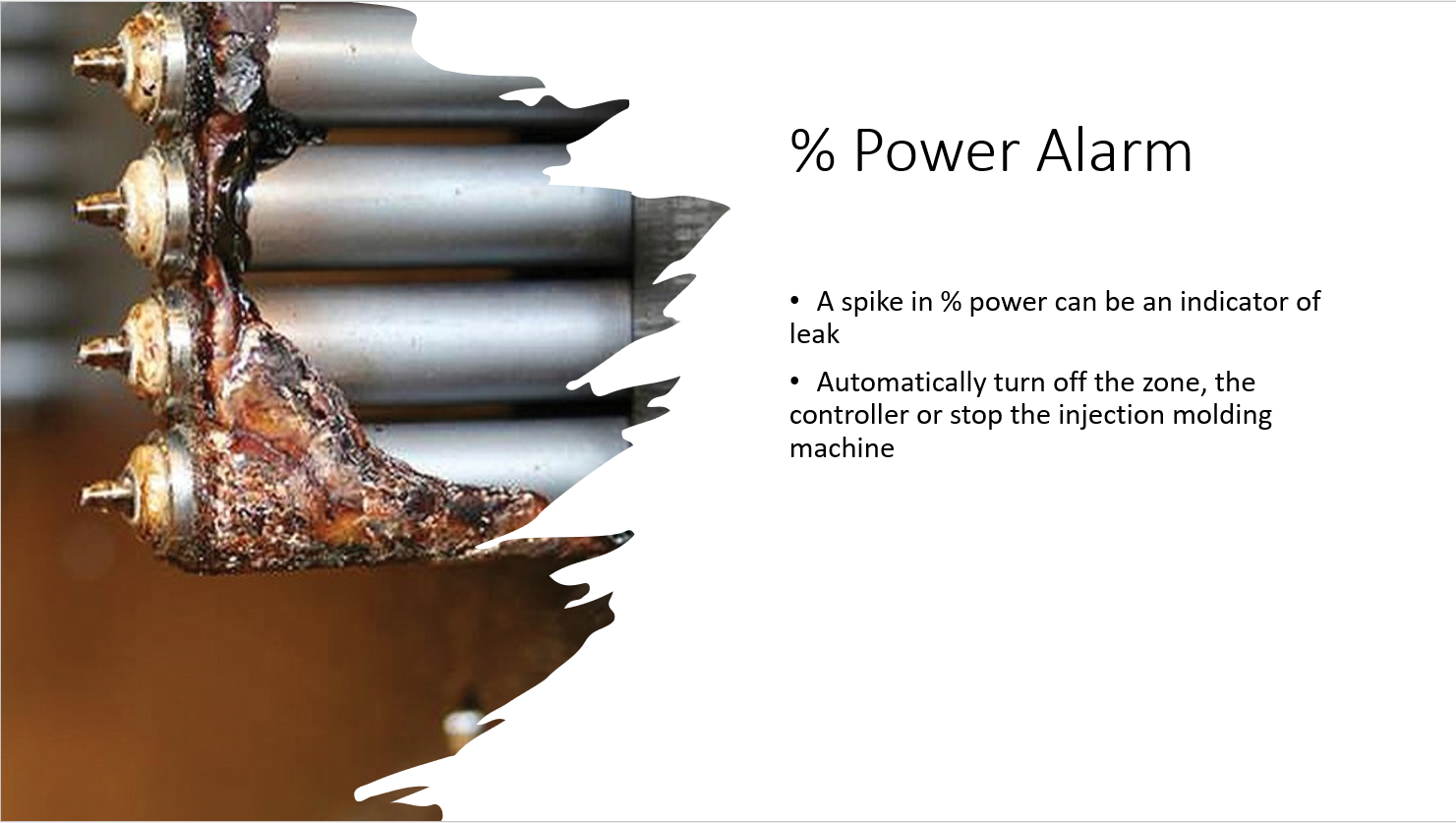

- % POWER ALARM – used to turn off a potentially leaking zone, the controller, or stop the injection molding machine. Detecting leaks early on prevents costly manifold repairs and mitigates downtime.

- OVER/UNDER TEMPERATURE ALARM – used to change a conveyor direction toward an inspection bin to ensure potentially bad parts do not make it to a customer.

- ALL OTHER ALARMS – TC OPEN, TC REVERSED, TC SHORTED, HEATER OPEN, TRIAC SHORT, OVER/UNDER AMPS – Stamp your injection molding machine history with alarm tags for a more complete process record.

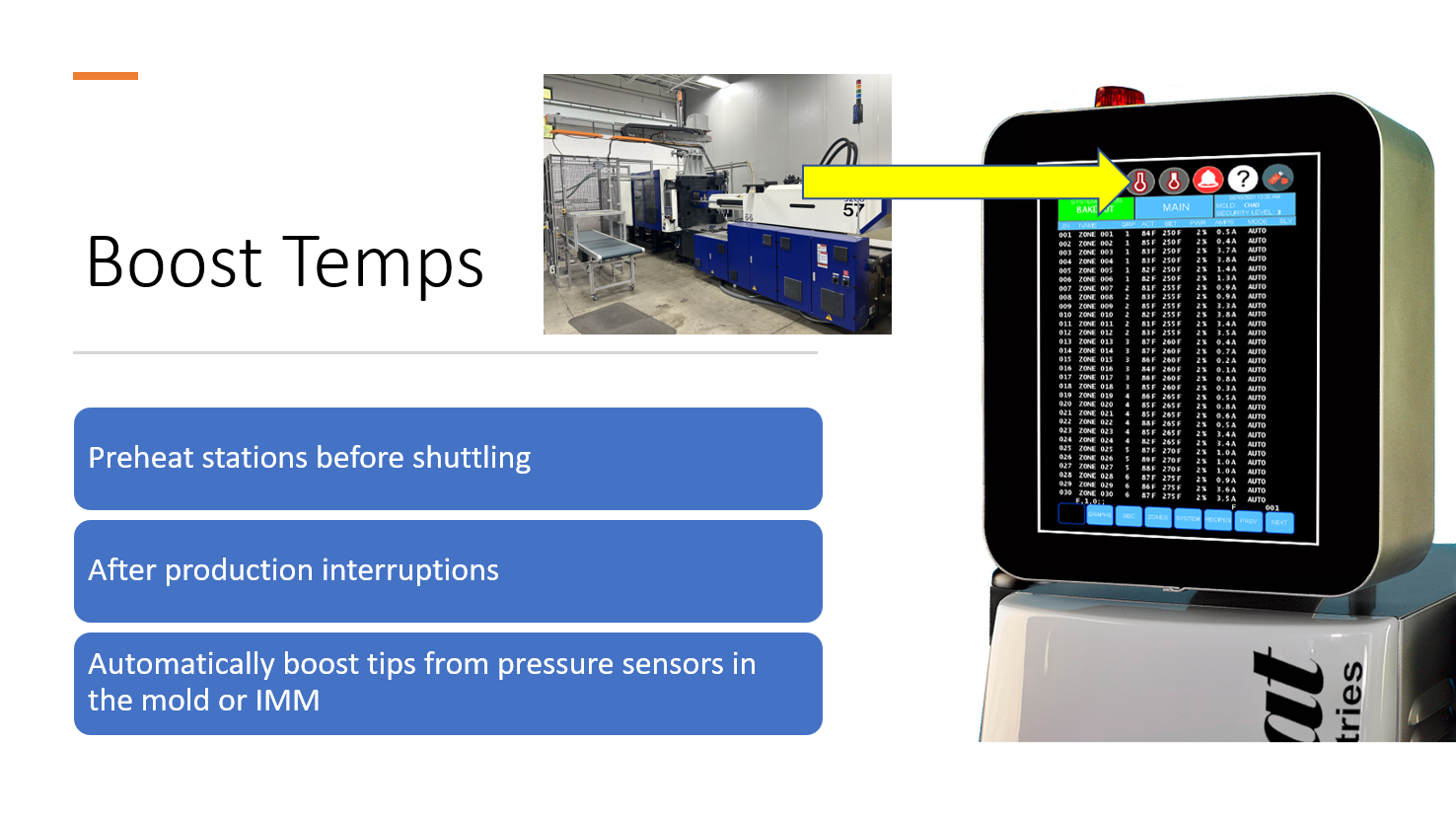

- BOOST – trigger from an injection pressure setting or automatically boost zone temperatures after the injection molding machine has been sitting idle or with preheat stations before shuttling.

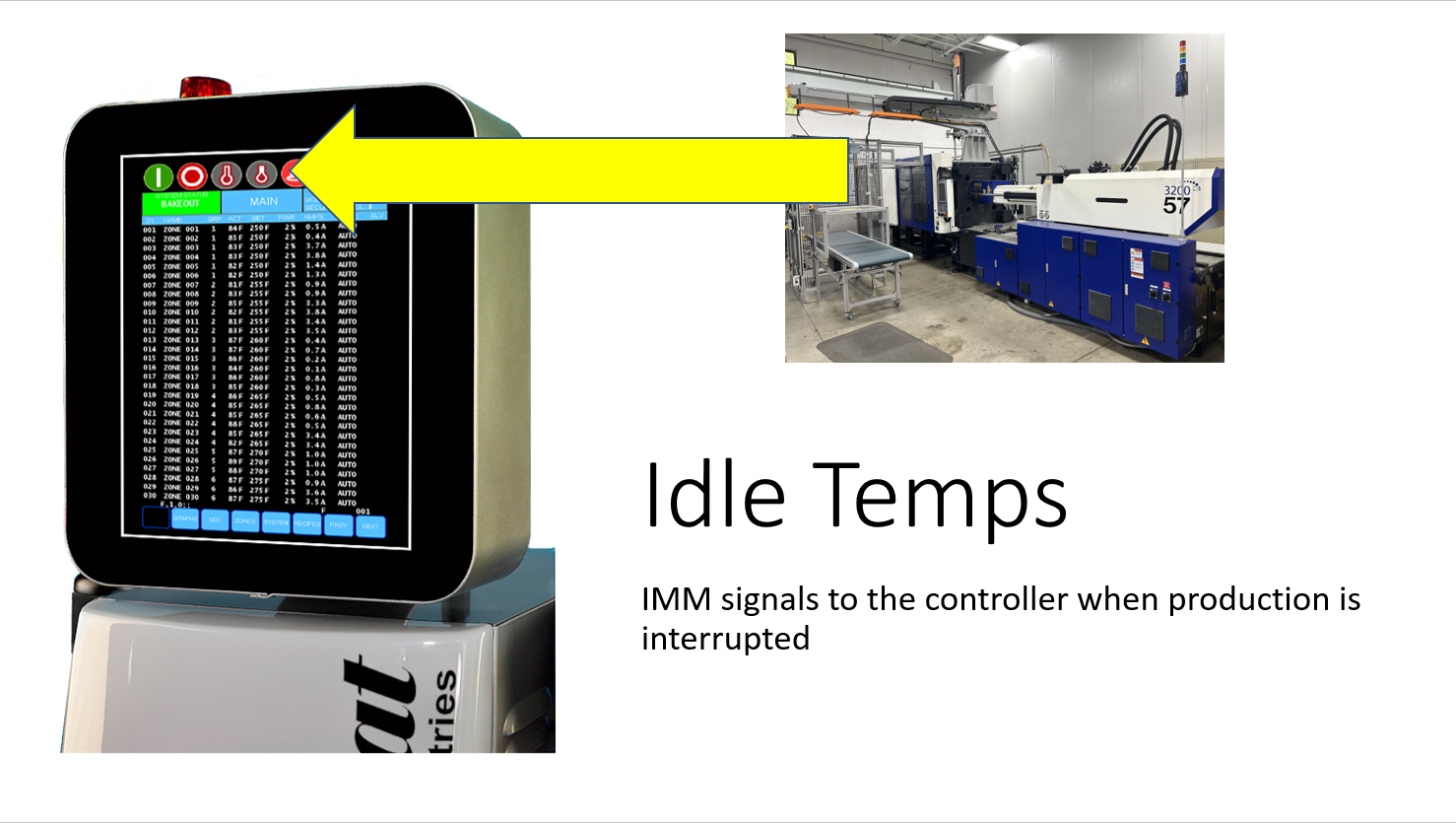

- IDLE – automatically lower zone temperatures from the injection molding machine during production interruptions. This prevents material degradation and minimizes the risk of dangerous “spitting” of hot material from the gates while the mold is open.

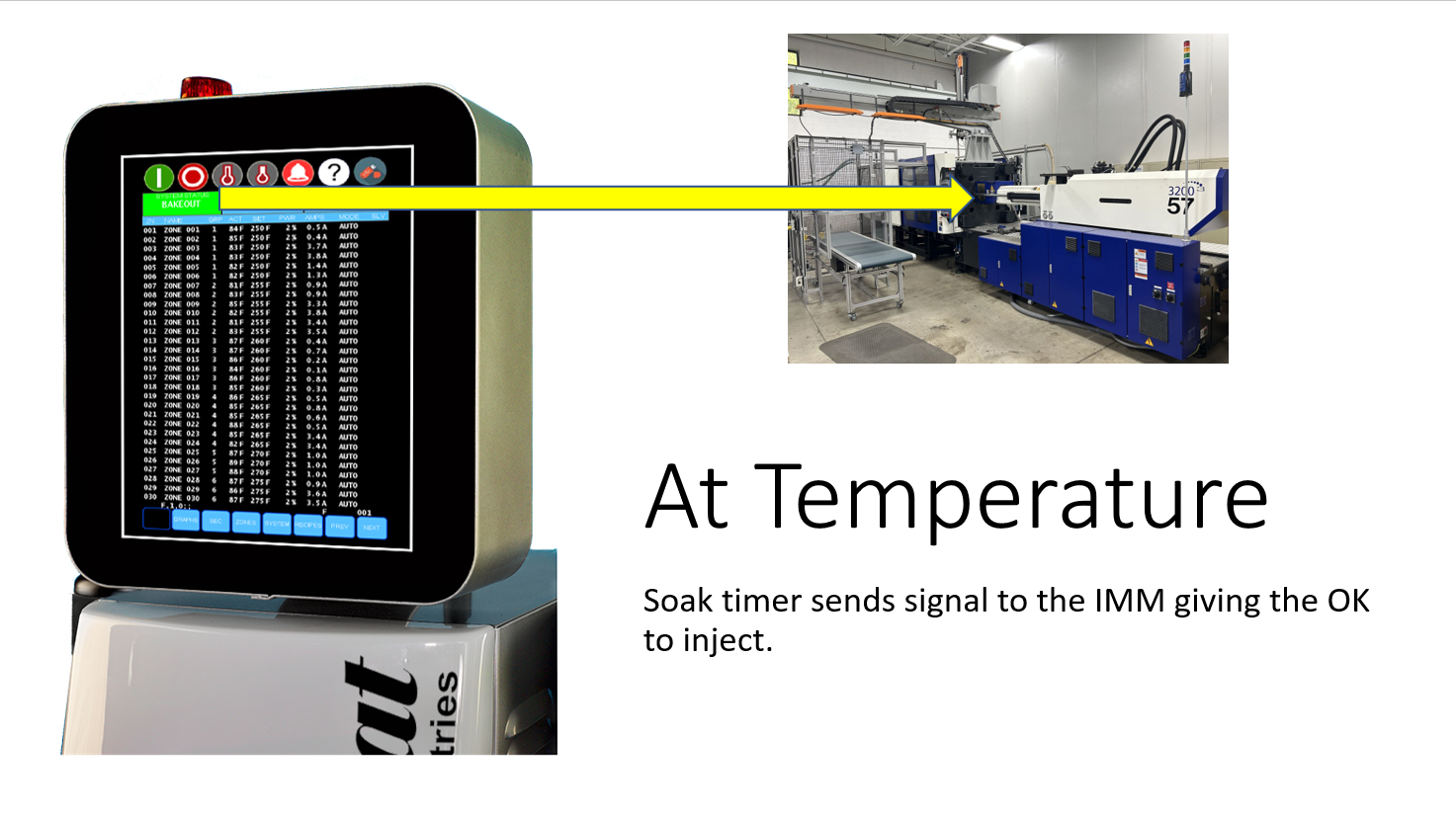

- AT TEMPERATURE – give the injection molding machine the all-clear to inject once the SOAK Timer ends.

Reference: Hot Runner Troubleshooting

Hot runner input output signals are a great start to injection molding machine integration. Fast Heat Pulse Hot Runner Controllers also include VNC Viewer as a standard feature. Use a VNC Viewer application on the injection molding machine display or any computer that is on the same local area network as the controller’s HMI. Enter the IP address of the controller HMI in to the VNC Viewer application in order to remote control the device.

Click here for more details about the Pulse Hot Runner Controller.