Screw Tip Assemblies

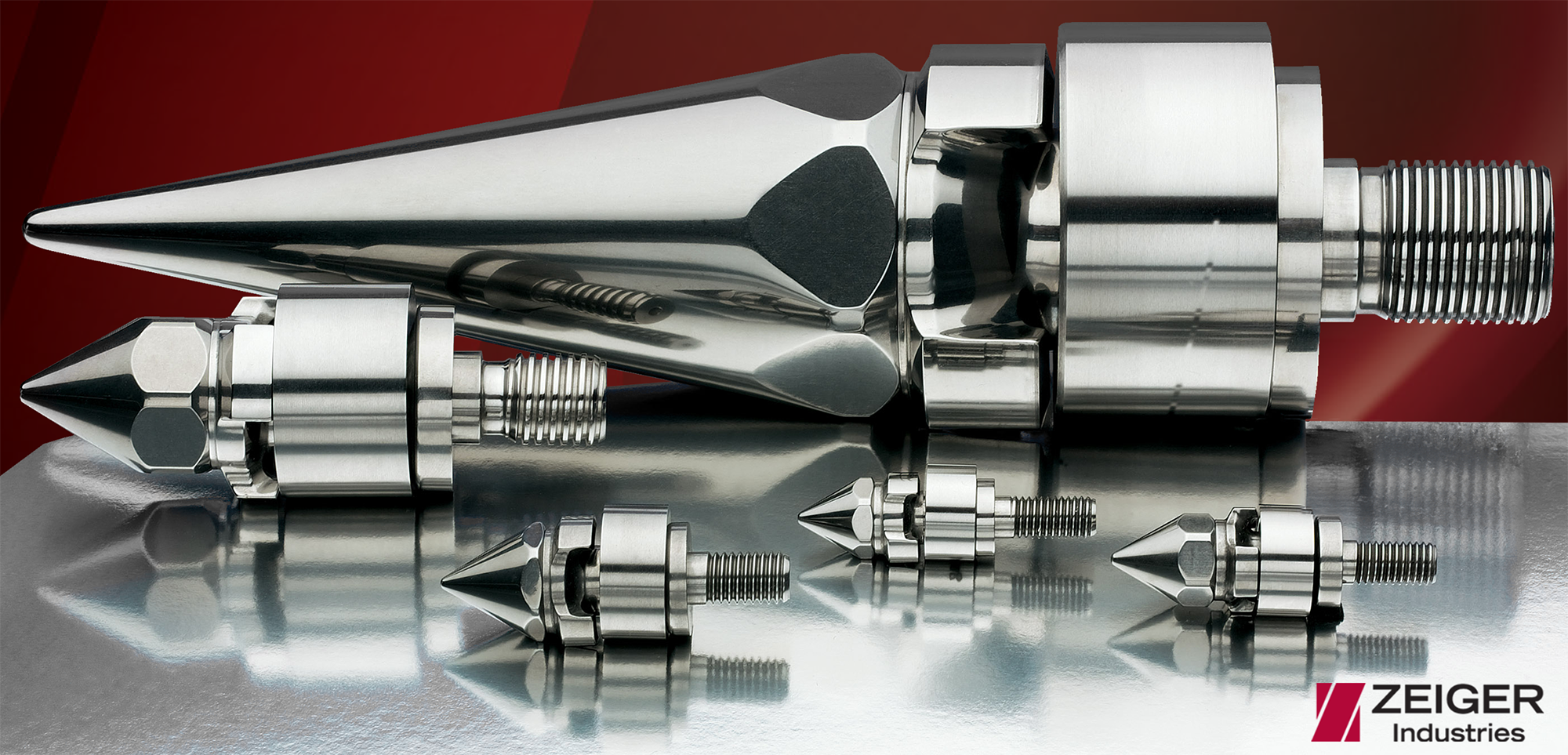

MALLARD® Z4 injection molding screw tip assemblies, also known as check valves, are the gold standard for solving early wear due to abrasion and corrosion. Utilizing a building block design concept, MALLARD Z4 valves provide numerous advantages for any processing need, including:

- Numerous design and material selections (optimize for wear and/or corrosion resistance)

- Replaceable wear components

- Tough, reusable stainless steel retainer

- Self-cleaning full-flow design (prevent black streaks)

- Industry best for shot to shot 2-year wear-through guarantee on our carbide faced valve option

Our designs allow use of the same retainer and rear seat, and incorporate a replaceable front seat and check ring concept. That saves you money and allows for easy customization of your valve for any need. The MALLARD® Z4 line of check ring valves provides the latest technology for reliable performance.

How to Choose a Screw Tip Assembly

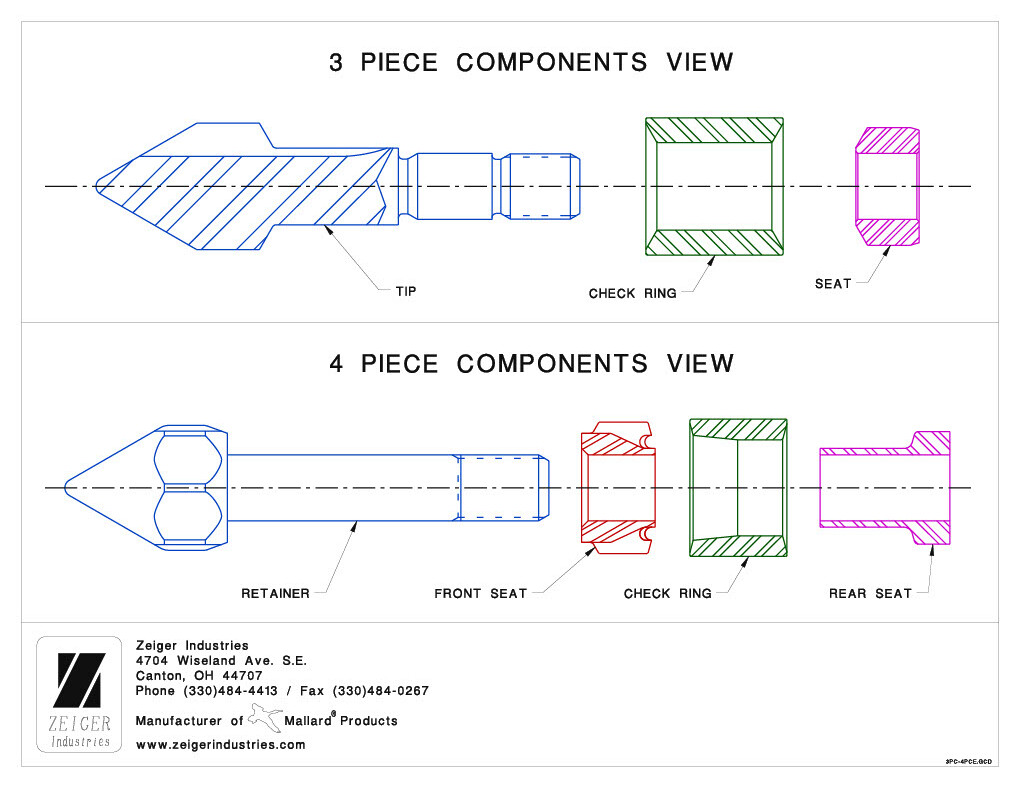

There are numerous options for screw tip assemblies, also known as valve assemblies or check-ring valve assemblies. We offer a 4-piece valve assembly for the following reasons:

- It can be customized for corrosion and/or wear resistance.

- The rear seat dimension can be customized for faster shut-off.

- The retainer tool steel is optimized for strength.

- The front seat is optimized for high wear and high hardness.

- The check ring is optimized for high wear and high hardness.

- The rear seat is optimized for high hardness.

These advantages far outweigh and cost difference to a generic 3-piece assembly that is prone to cracked retainers and requires complete retainer replacement when the the check ring contact area is worn. With our 4-piece assembly, we simply replace the front seat and ring as needed. For long-run abrasive applications, we offer a carbide faced ring and front seat.