Heat Transfer and Uniformity by Zeiger and Spark Industries

Okay, one more time for those of you who may have missed it…for those way in the back…anyone who knows anything about injection molding knows the importance of having optimum control over heat profiles…it is top priority! Temperature affects every step of the injection-molding process and must be appropriately managed.

Further, inadequate or excessive temperatures can leave flaws in the finished product and damage the injection machine. During the injection process, temperatures that are too low can lead to flow marks or wavy lines on the surface of the finished part.

Identifying and controlling the temperatures at each point throughout plastic injection molding will ensure that the process runs smoothly. Knowing the flaws that can occur in the finished product and the temperature control errors that create those flaws allow for quick troubleshooting. Moreover, correcting undesirable results while yielding quality parts and increasing efficiency.

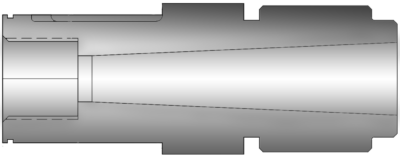

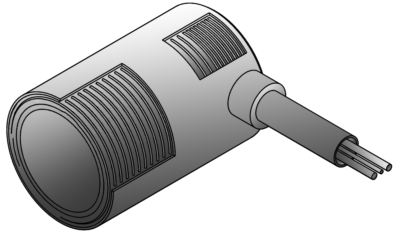

Recently adding another piece to the controllable set, Zeiger and Spark Industries have collaborated on a new heated tapered nozzle designed for reduced pressure drop and self-cleaning operation. Equally important, is the ability to work with aggressive materials.

The nozzles launched at the PTXPO (March 28-30) are available for all injection molding machine brands and sizes with a sweet spot within small-to mid-tonnage machines.

The nozzle body is constructed from hardened PM stainless tool steel, and its melt channel features a continuous taper. This design allows for self-cleaning and more rapid color changes.

Additional features:

- Swaged stainless steel construction

- Precision wound, high-surface-area heating element wire

- Replaceable thermocouple

- Maximum pack density of the internal ceramic

- Long-lasting

Check out more details at Heated tapered nozzle launch

Of course, reducing material waste, maintenance downtime, and fewer poorly molded parts

are advantages of using a heated nozzle. Again, continuity, control, and consistency throughout the process and from end to end are vital.

Fast Heat by Spark Industries, in conjunction with Zeiger, is here to help perfect your processes.

Reference: