Consistent Hot Runner Temperature Control is Key

We’ve known for many years that Fast Heat clients value precise hot runner temperature control, especially for engineered resins, glass-filled applications and wide-spec regrinds. These materials require consistent temperature control to achieve “part-to-print” specifications. According to CAE, a leader in Moldflow analysis, altering material characteristics due to inconsistent temperature control is a common cause of warpage.

Another aspect of achieving “part-to-print” specifications, as CAE calls it, are process settings. Again, the key to temperature control is not to introduce variation into the process due to fluctuating temperatures. Simply put, the manifold system is merely a passageway for the melt that is already supposed to be plasticized correctly by the injection molding machine. While gate location, gate type/size and sequential valve gating are an integral part of proper Moldflow recommendations, consistent hot runner temperature control is required to convert molding simulation to reality.

Here is a sampling of the feedback we have received from Fast Heat hot runner control users:

- “We need Pulse to achieve the critical gate temperature control required to mold thin-wall parts with challenging part geometries.”

- “We had a problem molding Santoprene onto a pre-molded polypropylene part. We were experiencing inconsistency in part quality, ranging from short-shots to flashing. Fast Heat supplied a 12-Zone Controller. We immediately began producing quality finished parts.”

- “The controller is great!! We have not had any of the issues with this tool like we saw before.”

Hot Runner Control is Only a Piece of the Puzzle

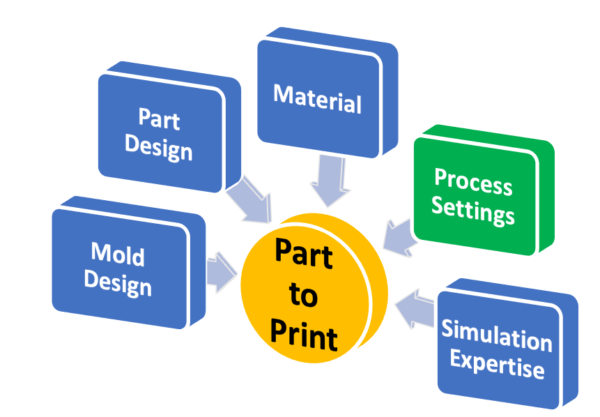

According to CAE, there are five ingredients required to achieve “part-to-print” specifications. They are:

- Mold Design

- Part Design

- Material (impacted by hot runner control)

- Process Settings (impacted by hot runner control)

- Simulation Expertise

Fast Heat by Spark Industries is committed to our client’s success. We are reaching out to other resources in the industry to advance our understanding, implement impactful improvements to our offering and share these resources with the molding community. CAE is offering a special webinar specifically for our clients and connections within the industry.

Special “Part-to-Print” Webinar by CAE Services, Dec 7, 2021

Join this webinar Dec 7, 2021 at 11:00 ET to see how CAE Services’ Experts attack warpage problems by avoiding them in the first place.

- Learn how decisions about mold design, part design, materials, and process settings affect the final dimensions of your part.

- Learn strategies for using Moldflow simulation to get your plastic part dimensions to print even before production startup.

- Discover how Part-to-Print improves costs and timelines for plastic part production.

- Engage with an in-depth topic discussion with questions fielded during the presentation plus Q&A at the end of the webinar.

References: