Hot Runner Maintenance Using the MoldXChecker®

Just like you would connect your hot half to a hot runner controller, you can now connect to the Fast Heat MoldXChecker®. If you’re wise and use the Mold Checker in the tool room, you would also know if you had an open heater. Waiting until you have a mold on the press to find out you have an open heater means you wasted all of the time. To troubleshoot an open alarm on your controller on the shop floor, you’d have to backtrack through your connectors and cables and then climb up on the tool (dangerous!) to check your mold box wiring and heater for that zone. If you truly have an open heater, you’ll need to pull the tool. And it is really easy to make a mistake when working top of a platen with tiny connection pins.

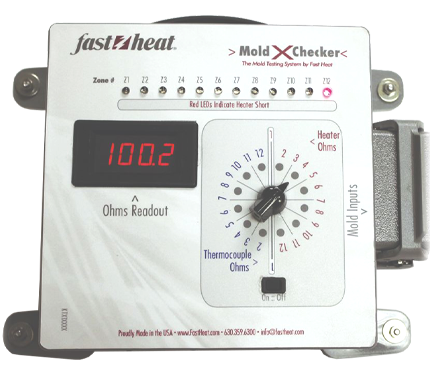

A best practice would also be to have a MoldXChecker® at the machine so you can double-check for dead shorts before turning on your controller! Use the separately wired circuit in the Mold Checker with the dial in the vertical position. If there is a short, you’ll see that zone # light up.