Hot runner maintenance covers preventative maintenance, troubleshooting, training, repairs, diagnostics, and cable/connector issues.

Click on this link to examine the Mold Making Resource break down on the benefits of hot runner systems.

Highpoints of hot runner systems:

• Ability to minimize gate vestige

• Uniform wall thickness

• Lower cycle times

• Less waste

• Reduction or elimination of knit lines

• Great for high cavitation molding

• Often the only method for micro-molding. The center-to-center distance of the hot runner tips is as little as 17 mm.

• Standardization of components can mean significant savings in material and manufacturing

• Many large molds rely exclusively on hot runners. Cold runners cannot meet the demands

You see it is all integral; the pieces of training, just like the information on what should be checked and maintained, the why, is all tied together.

In-house maintenance and repair mean a faster and more cost-effective turn around. It is good business and makes logical sense. Packing up and shipping out equipment and then waiting endlessly for it to be returned and paying an outside vendor for transport and an outsourced shop for the repair; costly. Further, keeping a shop on schedule is hard enough without these types of extensive delays.

If done properly, the how and why training will help your technicians be aware of possible issues before they even occur…again, applying that practical knowledge gained in training.

Your in-house maintenance team will also benefit from the personal skill development, as well, meaning increased confidence, and professionalism.

• Crucial Training Points

Mold Making Technology breaks down some of the basics in cleaning and repairing a manifold within a typical hot runner system:

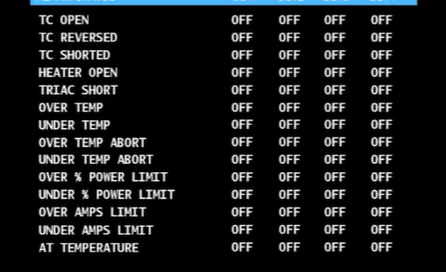

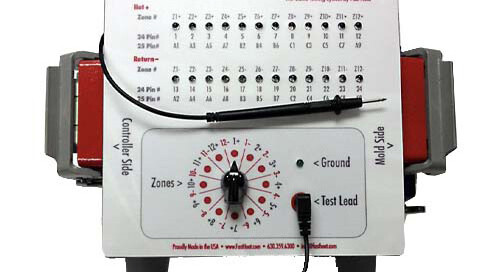

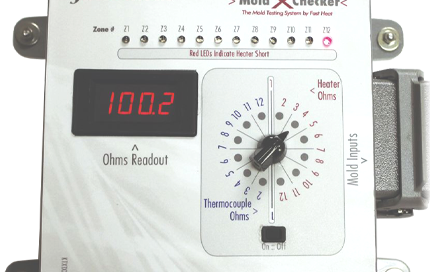

• Map out systems (ohmmeter) for position verification of thermocouples and heaters.

• Perform heater and thermocouple resistance and connectivity checks and replacement. If a heater or thermocouple has failed, compare its resistance to “good” thermocouples to see if other are close to failing.

• Verify correct thermocouple operation/ location and replacement.

• Route (to connectors) and splice wires correctly.

• Disassemble and clean valve gates (valve pins, seals and cylinder components).

• Inspect and verify tooling conditions, and check manifold stack dimensions for proper preload. Measure components at both room temperature and operating temperature and record how long it takes to “soak” the tool before fully expanded. This is the soak time you need to use when setting the tool in production.

• Perform comparative (cavity-to-cavity) dimensional analysis on nozzle and gate tip heights.

• Remove, clean and reinstall fixed (thermal) gate tips (sometimes done in the press).

Spark Industries has created a guide for new mold-making and molding professionals on hot runner maintenance training. We hit some highlights below but you can check out the full piece here:

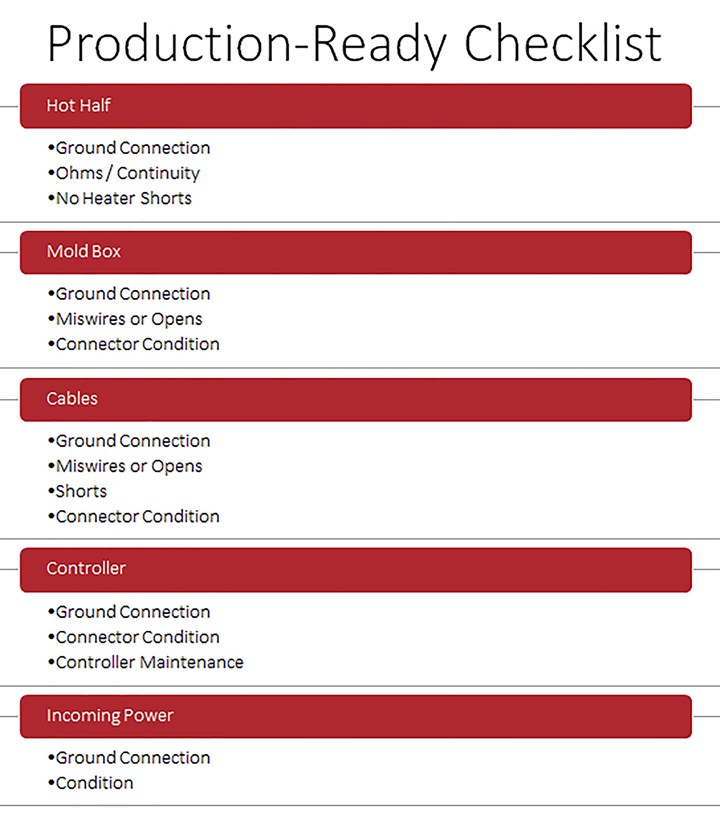

The Production Ready Check-List can be obtained here: Hot-runner-maintenance-training

Reference:

https://fastheatbyspark.com/hot-runner-maintenance-guide/