How will you minimize downtime and costly hot runner repair in your shop?

The answer isn’t as complicated as you might think…here’s how Fast Heat by Spark Industries will help!

You already know preventive maintenance is critical to the success of your shop. There will always be some amount of hot runner system repair, but if you keep on top of the preventive maintenance, your costs for hot runner repairs will be minimized…as will costly unplanned downtime. And the bonus results include more consistent high-quality part production and less material waste which translates directly into cost savings!

You can avoid miswires, open circuits, and shorts by making a routine check of these a part of your PM Plan. Have your techs check cables, pins, and the individual elements that make up the hot runner system before set-up and start-up…that’s the ideal scenario. Statistically, perfect start-ups mean better output.

After all, the advantages of using a hot runner mold are lost when the production job goes down for an extended amount of time…avoid unplanned downtime.

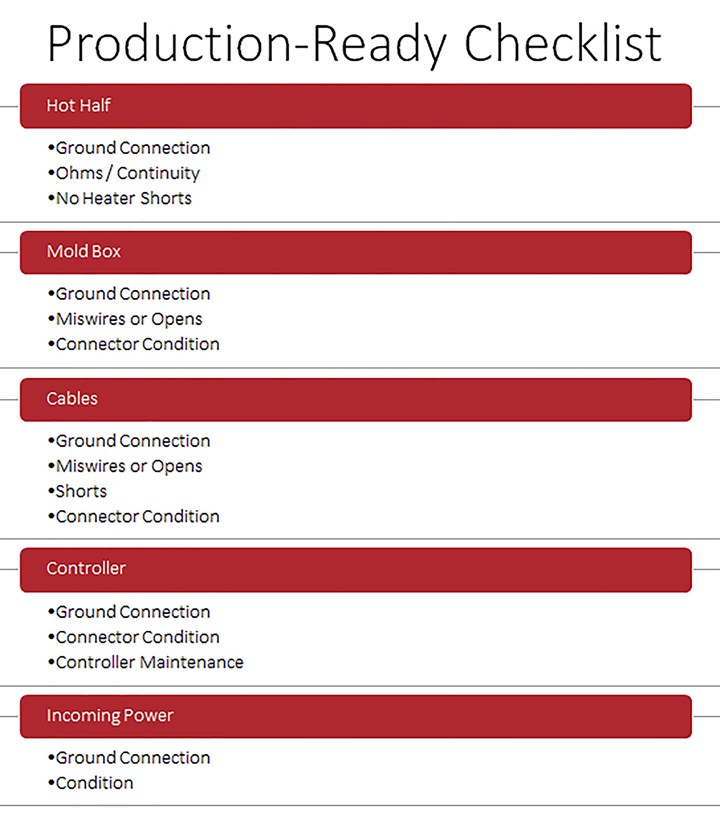

So, to start, let’s look at the items on your hot runner maintenance checklist:

Without exaggeration, examining the items above could easily include hundreds and hundreds of checkpoints!

How can you and your staff realistically do this for every job?

Fast Heat by Spark simplifies the tasks and breaks them down into two diagnostic categories and tools to assist you:

These diagnostic tools are made for REAL WORLD APPLICATION.

For example, you probably have a pile of cables in “limbo.” No one knows what may be wrong with them, and how often do these get mixed up with good cables making it back out on the production floor? Use the CableXChecker®

to analyze the issue. It is much easier to deal with before the job is up and running and will save you from wasted time and money!

The same goes for utilizing the MoldXChecker™. Avoid pulling the tool from the press by checking for problems while the mold is still in the toolroom.

Spark Industries will customize these diagnostic devices just for you.

Contact Us for More Information