Hot Runner Temperature Control: A Low-Investment Molding Solution

Processing challenges and mold design considerations amplify the importance of the use of hot runner controls and your molding solution.

Before we get started on the subject of using hot runner controls as a wide-reaching molding solution, we thought it worth mentioning where we are economically. The state of the economy absolutely causes lower-cost manufacturing solutions to be even more critical. We already know that tight budgets and supply chain concerns are definitely part of the challenges facing molders and manufacturers today.

So, is the US in a recession? Forbes states, “According to the general definition—two consecutive quarters of negative gross domestic product (GDP)—the U.S. entered a recession in the summer of 2022.”

How will you ensure that your plastic injection molding business continues to be successful amidst a recession… even if it is a “light” recession?

The possible answers include the following:

- Sound decision making

- Listening to and placing your customer first

- Processing advancements

- Having a competitive edge

- Select more profitable markets and improve performance in existing markets

- Cut out unnecessary waste/costs

There are as many options to resolve plastic injection molding challenges as there are challenges. Still, you want to have access to the best and most effective lower-investment molding solutions available. Utilizing hot runner temperature controls solve a multitude of injection molding issues.

In general, molders are constantly challenged to use older equipment and deal with high material costs.

Business must be done on an increasingly more efficient level; supply chain issues and higher material costs are not going away anytime soon.

Making it even tougher, consumers have a constantly expanding demand for new and increasingly innovative and complicated products. These products will be supplied by companies that can understand their customers and deliver products at a good and fair price while still remaining profitable. Molders have to minimize downtime and also reduce scrap whenever possible.

Improved hot runner temperature control can provide the competitive advantage needed.

What’s the big deal about hot runner control systems, anyway, you ask?

Maintaining the hot runner system at an accurate and uniform temperature through the heating and cooling phases of the molding cycle is not easy. Major quality problems are caused by the inability do this. Temperature consistency is important in avoiding resin deterioration and consistent part weight, for example.

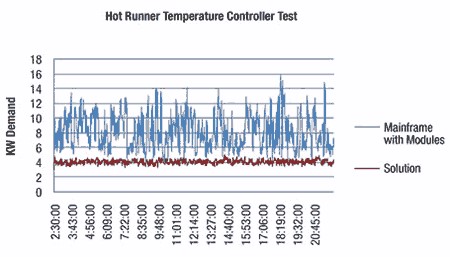

In addition, overlooked lower power consumption is an overlooked advantage of a hot runner control system.

Check out these power consumption case studies: Molding Solutions Case Studies and a full list of how you know which controller system is best for you.

Below is a partial list of considerations when selecting a hot runner temperature controller:

- Does the controller supply power to zones individually or in consideration of the entire system? It should consider the entire system.

- Does the controller read each zone many times before responding and then respond to a predicted trend? It should have predictive capability.

- Is the controller easy for all users to learn and operate? Are all functions used, or are only those easily found and understood? We believe all functions should easily be learned and used with a simple start-up guide.

- Does the controller automatically detect and alarm mold problems, or must you initiate the process? We believe automatic, real-time response is safer and more reliable.

- Does the controller offer molding cell integration to prevent cold shooting, tool damage, leakage, and unforeseen heater failure? Can all alarms be sent from the controller? Can the controller be remotely turned on, off, boost, or idled?

- Can the controller be stored in any position away from critical floor space?

- If you require transformers, how compact is the matching transformer?

Challenges and how hot runner controls can be your molding solution

Processing Challenges

Designers are demanding extreme sizes, tighter dimensional tolerances, and advanced surface characteristics to provide consumers with the products they want. However, molders often have to make the best use of older equipment which results in longer cycle times and less than-optimal operations as a whole. Less than optimum molding cells cause inefficiency in the entire facility—including electrical consumption and lower overall throughput, especially where molding is one of many links in the production chain.

Considering today’s molding challenges, improving hot runner temperature control now offers a significant opportunity to drastically improve results at a relatively low investment compared to other auxiliary and primary equipment.

After all, hot runner temperature control affects finished part quality and finished part quality affects your profit margin and customer satisfaction.

Using a temperature controller with predictive capabilities will save you from variations in all of the other plastic variables as well: flow, pressure, and time. Note that temperature has a much more significant impact on flow than the other variables.

Tooling Challenges

New part challenges directly translate into new tooling challenges.

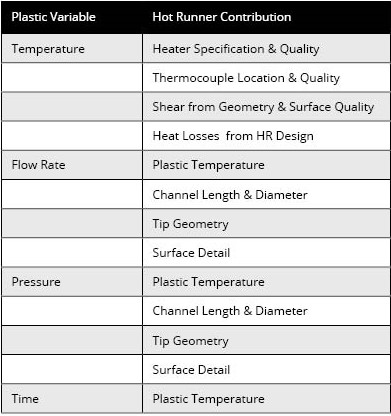

This includes the design, location, and consistency of heaters, thermocouples, flow channels, gate tips, water channels, manifolds, and plates. Figure 2 shows some of the ways hot runner design affects plastic variables.

Figure 2

Some basics to consider when evaluating your hot runner system design are:

- Are the thermocouples on the nozzles optimally located for the nozzle’s heat profile? They should be at a point of stable heat loss.

- Do all nozzles have a thermocouple? This provides optimal system control when using the proper type of hot runner controller.

- Is the entire system thermally balanced and managed with proper water channel size and location?

For the full list of considerations, click below.

Hot Runner Controls as a Molding Solution; Considerations

After taking all of those factors into consideration, you will find that you will want a controller that will predict and react to trends. Challenges can be overcome by using a hot runner temperature controller that manages all zones as a complete system while predicting temperature behavior. If zones simply respond every time there is a call for power, it will create instability within the system, no peaks or valleys. For stability in the process, you want the least amount of disturbance to the plastic as it travels through the hot runner system. Catching these issues quickly could mean the difference between a quick trip to the tool room and days or weeks of interrupted production. Capacity constraints due to unplanned downtime are costly and can be avoided with predictive capabilities.

Also, keep in mind that to maintain the hot-runner system continuity, proper startup of the hot-runner mold is essential…your technicians must understand that there are reasons why this is important. Check out our post: Hot Runner Maintenance Training Needs to Include Why Not Just How

Figure 3

Hot runner temperature controller that manages all zones as a complete system while predicting temperature behavior.

Benefits of a complete system predictive temperature controller:

- Makes it possible to mold more challenging parts.

- Reduces scrap.

- Predictable schedule utilization and higher overall throughput.

- Lower labor and managerial costs.

- Efficient electrical and cooling systems.

- Allows alternative resins to be used. This is a game-changing opportunity.

Fast Heat by Spark Industries offers a complete line of hot runner temperature controllers that present advantages like:

- Instant diagnostics with easy-to-see alarms

- Boost or idle with one button

- Quickly adjust set points by group within the hot half

- Ability to save recipes

Practical and High Tech – Always Working for You!

- ATP™ (Active Thermocouple Protection) automatically protects thermocouples from short-circuit current leakage while improving thermocouple signal accuracy.

- Extremely accurate, constant tuning PID algorithm, with 8.33 ms (milliseconds) power increments, prevents scrap and enables tight processing windows.

- Embedded software and industrial-grade components ensure long-lasting reliability.

- Waterfall Technology™ reduces peak KWh consumption.

- Simple, color touchscreen displays are easy to use, and you’re never more than one click away from the main page.

So, for a go-to, low-cost molding solution that can alleviate many of the challenges facing you on the molding floor, utilize a Fast Heat Hot Runner Controller.