Hot Runner Maintenance Training Needs to Include Why Not Just How

Onboarding and training new employees on why things are done a certain way and not just how is critical in hot runner temperature control and proper hot runner system management.

What does onboarding and training have to do with hot runner controls?

First, before we dive into the nuts and bolts of successful hot runner maintenance training, let’s examine the importance of effective on-boarding and of an established training system from a broader viewpoint. We assure you this is not a human resource piece!

For just a moment, allow us a little latitude, if you will, to look at humans and how we work. It makes sense in the end, and we will focus on hot runner control maintenance in short order, promise.

Most interesting, what we see now is a disparity between demand for talent and the number of workers willing to supply it. Blue Beyond Consulting notes that, “…well executed employee onboarding…can improve employee retention by 82%.

Also, due to this trend, it is more important than ever to provide onboarding and training that ensure your employees feel valued, prepared and supported.

Create an environment of success

Further, creating an environment of appreciation, self-worth and growth is essential. Train your employees, set them up for success, not failure.

Next, once you find the right employee, it is a must to set clear expectations and provide the right “tools” from the very start for their success and, ultimately, yours.

So, why address cause and effect? Psychology Today bundles it nicely and explains…well, explains why the why is important to people:

“…we are, all of us, meaning-seeking creatures. …why is what drives not only everything we do, but also our emotional reactions to everything that happens to us.”

“Interestingly, our acceptance seems to hinge less on how much we like the reason and more on how much sense the reason makes to us.”

This is key

Additionally, it seems obvious but it isn’t always taken into consideration unless specific focus is put on explaining the why we do things. Telling an employee how to do something is not the same as explaining the whole process. Employees can then apply that knowledge in similar situations and make an educated decision while applying reason.

Understandably, these are the employees you want troubleshooting and maintaining your hot runner controller systems. It’s almost like the old “Mousetrap” game…a domino effect…if this one little piece of the process doesn’t work, then nothing in the sequence is going to work.

Moreover, train them on the full picture of the process. Teach them how the controller works and how it interacts with the press and the mold. Train each level from operator to engineer on the basics. Why is it important to check the pins? Why are basic wiring configurations important? Do they know the foundations of plastic flow? What will be the result if each of the maintenance items are not PM’d? The answer, in its simplest form, is lost time and profit.

In conclusion, consistent high quality manufactured parts are the desired result. It is not only important to know how to get that quality part but why certain steps are taken to achieve that end each and every time. It makes everyone’s job easier to know the why!

- Benefits of hot runner systems

Many shops are apprehensive about taking on in-house tool and equipment maintenance. Molds and auxiliary equipment continue to be more complicated to maintain and repair. Hot runner molds continue to grow in application; it’s plain to see why when you examine the benefits of the hot runner versus a cold runner system.

Click on this link to examine the Mold Making Resource break down on the benefits of hot runner systems.

Highpoints of hot runner systems:

- Ability to minimize gate vestige

- Uniform wall thickness

- Lower cycle times

- Less waste

- Reduction or elimination of knit lines

- Great for high cavitation molding

- Often the only method for micro-molding. The center-to-center distance of the hot runner tips is as little as 17 mm.

- Standardization of components can mean significant savings in material and manufacturing

- Many large molds rely exclusively on hot runners. Cold runners cannot meet the demands

Finally, you see it is all integral; the pieces of training, just like the information on what should be checked and maintained, the why, is all tied together.

Good Business

Furthermore, in-house maintenance and repair mean a faster and more cost-effective turn around. It is good business and makes logical sense. Packing up and shipping out equipment and then waiting endlessly for it to be returned. As well as paying an outside vendor for transport and an outsourced shop for the repair. This is costly. Furthermore, keeping a shop on schedule is hard enough without these types of extensive delays.

In summary, if done properly, the how and why training will help your technicians be aware of possible issues before they even occur…again, applying that practical knowledge gained in training.

Your in-house maintenance team will also benefit from the personal skill development, as well, meaning increased confidence, and professionalism.

- Crucial Training Points

Mold Making Technology breaks down some of the basics in cleaning and repairing a manifold within a typical hot runner system:

- Map out systems (ohmmeter) for position verification of thermocouples and heaters.

- Perform heater and thermocouple resistance and connectivity checks and replacement. If a heater or thermocouple has failed, compare its resistance to “good” thermocouples to see if other are close to failing.

- Verify correct thermocouple operation/ location and replacement.

- Route (to connectors) and splice wires correctly.

- Disassemble and clean valve gates (valve pins, seals and cylinder components).

- Inspect and verify tooling conditions, and check manifold stack dimensions for proper preload. Measure components at both room temperature and operating temperature and record how long it takes to “soak” the tool before fully expanded. This is the soak time you need to use when setting the tool in production.

- Perform comparative (cavity-to-cavity) dimensional analysis on nozzle and gate tip heights.

- Remove, clean and reinstall fixed (thermal) gate tips (sometimes done in the press).

Highlights

Most importantly, Spark Industries has created a guide for new mold-making and molding professionals on hot runner maintenance training. We hit some highlights below but you can check out the full piece here:

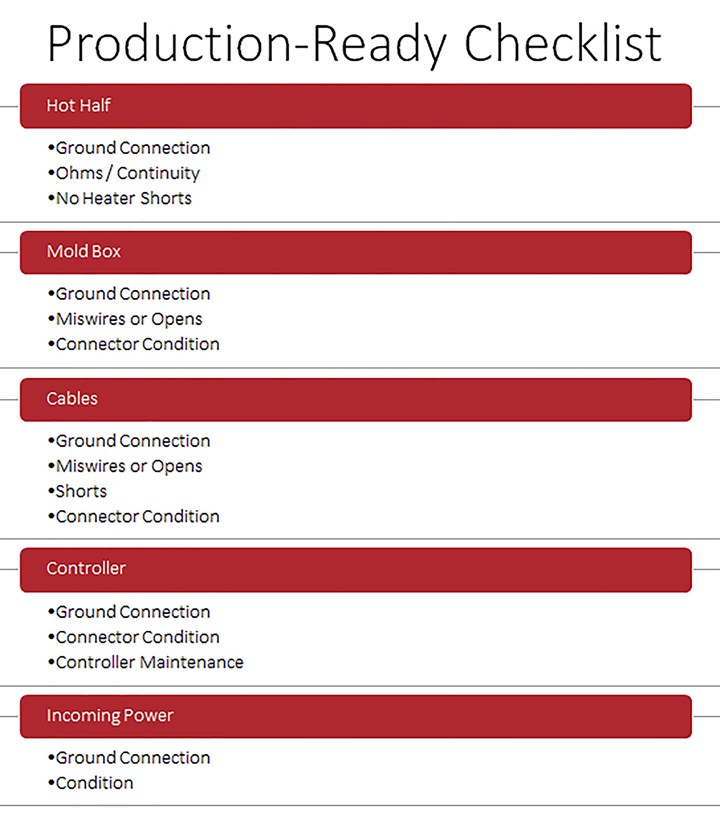

The Production Ready Check-List can be obtained here: Hot-runner-maintenance-training

And the full article may be directly reviewed at:

Mold Making Technology The-ins-and-outs-of-hot-runner-temperature-control

• Emphasized detail:

1. Hot Runner Heaters, Thermocouples, Grounding and Direct Shorts

Firstly, there is no sense in putting a tool into production only to have heater failure. So, routinely measure the ohms of each heater within the hot runner system and compare that measurement to its intended rating. You can easily see the resistance rise when you document ohms in a spreadsheet. This provides a timeline for proactive heater replacement. Also, an open circuit will be evident when checking ohms if a heater circuit is open or mis-wired to the wrong hot/return zone in the mold box.

Type J grounded thermocouples (t/c) are the most commonly used. Checking ohms on t/c circuits ensures continuity and consistent readings will identify if there is a reverse. You can determine a shorted t/c by applying heat to the intended t/c location. Ohms should rise. If there is a short (the t/c is closed at a different junction location), you will not see the same reaction.

Safety Issues

To begin, grounded thermocouples are susceptible to ground leakage from heaters when there is no effective ground connection between the hot half and the heater connectors. Most modern integrated controllers have an auto-slave or manual slave option that allows you to run a zone off a comparable zone’s t/c, in the event you lose one. In addition, some mold boxes and controllers provide a thermocouple protection device to address the ground leakage issue.

If a ground wire is securely and cleanly fastened to the hot half and each heater connector in the mold boxes, touch the heater connector legs to the hot half to check for direct shorts. If there is continuity, then a pinched wire or a heater sheath contacting a lead upon heating the system caused a direct short.

Finally, do not plug this tool into a hot runner controller and turn it on. A direct-short poses a severe safety hazard and damages thermocouples, connectors, cables and the controller.

2. Mold Box Connections and Grounding

Next, the mold box is a transition from the hot half to the heater and thermocouple cables. Additionally, based on the wiring diagram, wire each heater and thermocouple to the correct junction in the mold box and then from that junction to the back of the heater or t/c connector point. Some controllers allow reassignment of the thermocouple to a different zone if there is a mis-wire.

Lastly, ensure the heater connectors have a ground wire connected to the mold box and that the mold box is mounted directly to the hot half. The last thing to check is the connector pins and latches. Bent pins and pushed-back inserts are a common issue and a game stopper. Broken or missing latches will cause intermittent connections, leading to intermittent alarms, poor t/c readings and open circuits.

3. Heater and Thermocouple Cable Connections and Grounding

Heater and t/c cables have the same potential issues as mold boxes, including mis-wires, opens, shorts, missing or bad ground, bent pins and pushed-back inserts.

Moreover, cables can also have physical wear and tear, especially around the strain areas near the connectors. Ideally, cables should have service tags indicating that they are production-ready.

4. Hot Runner Controller Connectors, Maintenance and Grounding

Connectors on the controller have similar issues as connectors on cables. For example, pushed-back inserts, bent or missing pins, broken or bent latches, loose or missing ground wire connections.

The controller will have specific maintenance requirements as well. For example, you must update and clean filters, cooling fans, power module fuses and board components to ensure they function as designed.

5. Incoming Power and Grounding

Furthermore, variable frequency drives (VFDs), servomotors, poor incoming power quality and poor in-plant grounding can negatively impact hot runner temperature control, so make sure that all VFD and servomotors have shielded cables. The hot runner cables should also be shielded and not run parallel to high-voltage lines. If the facility’s earth ground is inadequate, you may have to drill a hole in the floor and drive a copper grounding spike at the machine.

In closing, a wise individual once said something along the line of, “people don’t fail, systems do.” That’s a big say coming into a manufacturing facility in the plastic injection molding industry; there are so many moving parts. Being a part of the maintenance and repair of the equipment in these facilities requires accurate, well-structured and solid training that goes beyond the how. Include the why and you will set up your team for success.