Preparing for Production – Hot Runner Maintenance Guide

This guide includes the blog post below and an adjoining slide deck. The blog post below is a reference guide with links to detailed explanations and visual examples we have compiled over the years (photos and videos). Use the adjoining slide deck for a speedy review of hot runner maintenance best practices. See the bottom of this page for the table of contents.

Download the adjoining slide deck here: >231110-SPAR-Production Ready Maintenance Guide

Training

Firstly, this section focuses on maintenance training and includes our tips, outside resources for reference, 3rd party training opportunities, and a software recommendation to help manage tooling maintenance responsibilities.

Click here for the entire training post: >Training w/ Cleaning & Repair Checklist.

- >Hot Runner Pre-production Checklist

- >MoldMaking Technology Article

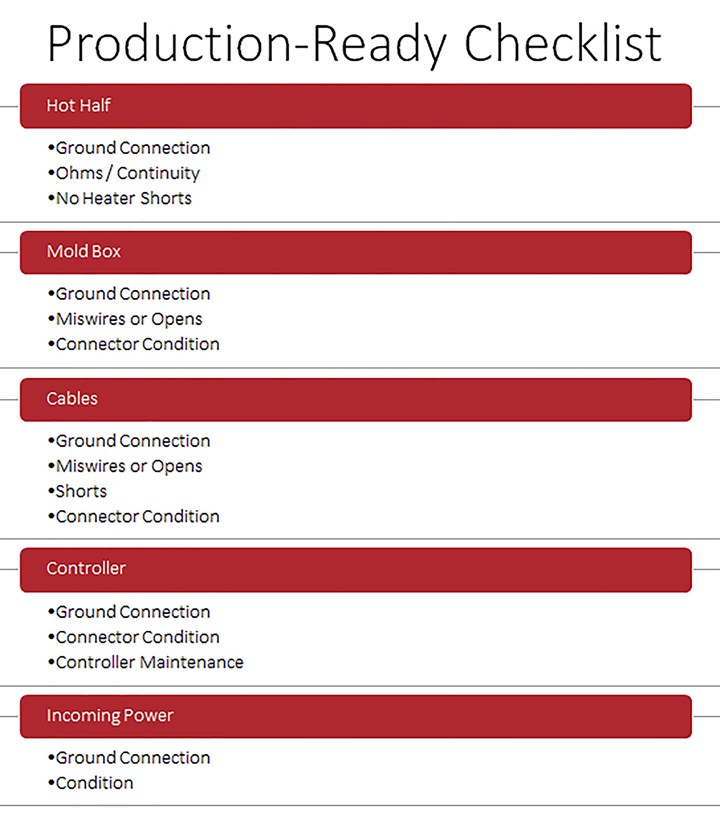

- Special Note: You Must Check Grounding the Hot Runner, Mold Box, Cables, Controller, and Incoming Power!

- >Hot Runner Troubleshooting & Repair Course – American Injection Molding Institute

- >MoldTrax Tracking Software

Hot Runner Cable Testing

Secondly, Click here for the full post: >The Problem with Hot Runner Cable Testing

- Easy to Make Mistakes

- Importance of Checking for Shorts

- Time-Consuming

- >Connector Anatomy and Typical Problems

Hot-Half Inspection

Click here for the full post: Hot-Half Wiring Inspection the Old Way vs. MoldXChecker®

- Includes How to Test:

- Resistance of Heaters and Thermocouples

- Direct Shorts

Further, please check your Productivity Series, Topic 2 Maintenance email for downloads of our Maintenance Guide for Fast Heat Hot Runner Controllers.

Adjoining Slide Deck Table of Contents:

Slide 1 – Intro

Slide 2 – Production-Ready Checklist w/ link to our full training post.

Slide 3 – Inspect hot runner components at room and operating temp to determine actual “Soak Time.”

Slide 4 – Features of MoldXChecker®

Slide 5 – Importance of Measuring Thermocouple Ohms

Slide 6 – Hot-Half Ohms and Direct Short Testing the “Old Way”

Slide 7 – How to use the MoldXChecker®

Slide 8 – Checking for Hot Runner Ground

Slide 9 – The Problem with Shorts in a Hot Half

Slide 10 – Intro to CableXChecker®

Slide 11 – How to use the CableXChecker®

Slide 12 – How to Build or Repair a Cable

Slide 13 – The “Old-Way” of Checking Cables

Slide 14 – The Problem with Shorts in Cables

Slide 15 – Summary of CableXChecker®

Slide 16 – Connector Maintenance and Troubleshooting

Slide 17 – Recommended 24-Pin Connectors

Slide 18 – Hot Half Measure and Heating Procedure

Slide 19 – Quiz

1. Why measure t/c ohms?

2. Can you repair a shorted heater cable?

3. At what temperature should you check a hot half for direct shorts?