Plastic Injection Molding Process Options Explained | Trade Show Dates

Yes, Fast Heat by Spark Industries is all about injection molding solutions! We also want to ensure you have easy access to whatever makes your business successful.

We believe that straightforward education and training are part of the obvious advantages you can bring to your staff and business practices.

The injection molding industry has some pretty remarkable options that you can consider when designing new product lines and molds. Some of these processes can help utilize certain resin types or even make your product more durable.

For example, look at these

- 3-Plate vs 2-Plate

- Cold-runner vs Hot-runner

- Insert molding

- Over-molding

- Two-shot

- Vertical

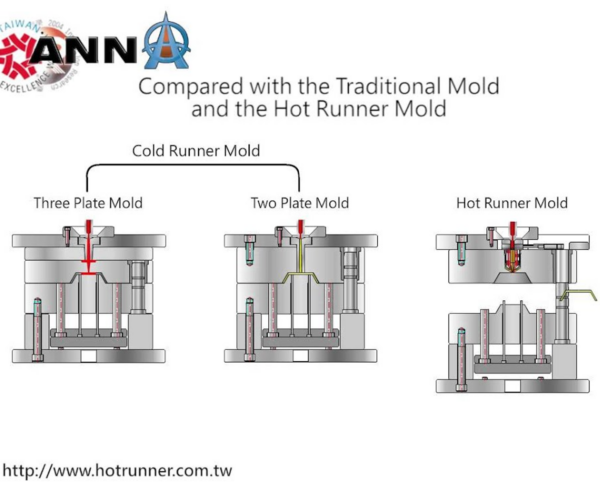

3-Plate Versus 2-Plate Molds

As implied by the name, the 3-plate mold is more complex than a 2-plate mold. It has an additional mold plate between the top clamp plate and the cavity plate, called the runner plate, which allows the runner scrap and plastic molded parts to be released separately.

A 3-plate mold is cheaper to build and less likely to break down. Also, thermally, some sensitive materials are less likely to degrade.

However, the 2-plate application can save money and time for mass production. Further, the 2-plate mold drops the plastic part freely. But after molding, there’s a need to manually cut off the gate, which requires more time, and an operating technician, which means additional costs. However, choosing a gate shape and location with a 2-plate mold is easier.

FS Tooling helped us get a good grasp on the differences; take a look at how they expand on 2-plate vs 3-plate explanations for a fuller picture.

Delving a little further, when it comes to plastic injection molds, the most common division is between cold runner and hot runner molds. In general, hot runners are more expensive than cold runners but also offer better performance and durability.

According to the basic injection mold gating system, systems can be divided into three types:

- Two-plate mold

- Three-plate mold

- Hot runner mold is also called (runner-less mold)

Of course, Fast Heat by Spark Industries may be a little partial to the hot runner system! But every project has different requirements.

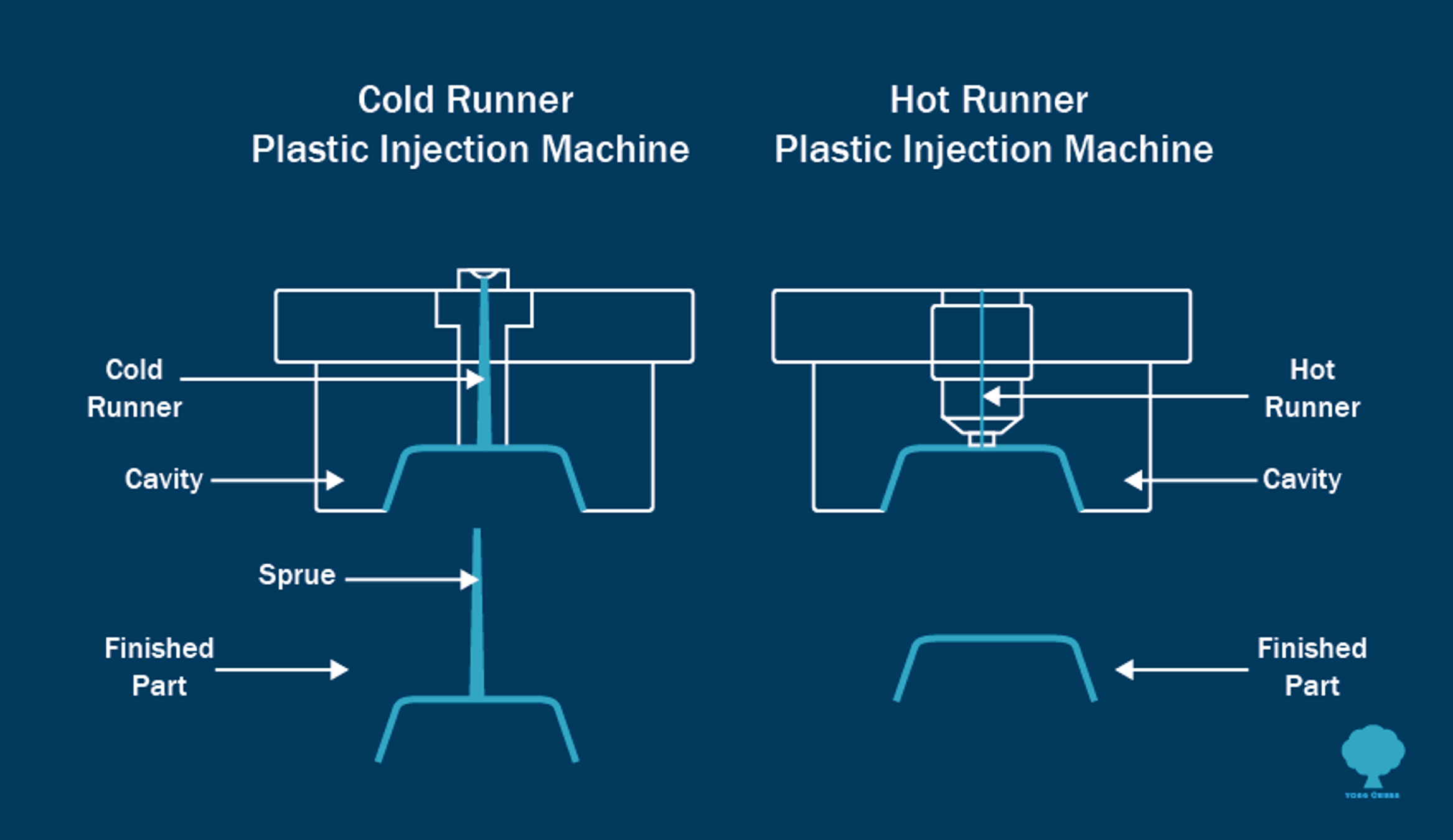

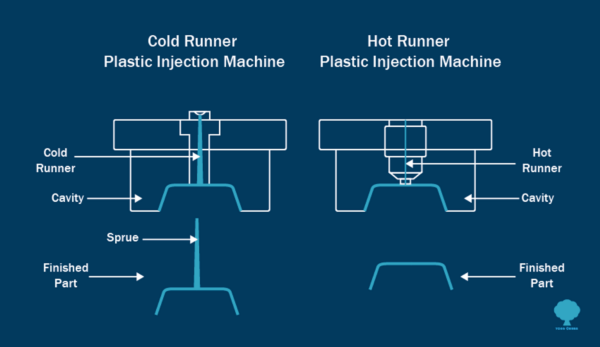

Cold Runner vs Hot Runner

Mold Devices explains the difference between hot and cold runner injection molding:

Hot runner mold systems are valued for their ability to produce consistent quality within faster cycle times. Although more expensive than cold runner systems in terms of initial cost and ongoing maintenance, they don’t generate waste, thereby offering long-term savings potential. Downsides of hot runner mold systems: Color changes are more difficult, and they rule out the use of some heat-sensitive polymers.

Cold runner mold systems allow for easy color changes, work well with heat-sensitive polymers, and are less expensive and easier to maintain than hot runners. Disadvantages: They offer slower cycle times and create waste unless excess materials are recyclable. As a result, cold runner mold systems can run up higher costs if several iterations are required to arrive at the correct design.

Ok, so you have a good grasp on choosing hot or cold runner systems and understand the difference between two and 3-plate molds…here’s what some consider to be advanced molding techniques! If nothing else, they are really cool!

We gathered this information from Sybridge.com, and the full article can be seen at: Insert and over-molding:

Insert Molding

The insert molding manufacturing process involves injecting molten plastic around pre-placed inserts (usually metal), forming a strong bond between the two materials and helping cut back on assembly operations and time. Common inserts include pins, blades, threaded nuts and knobs, sleeves, bushings, and the metal shanks of tools, such as screwdrivers.

Over Molding

First, a thermoplastic injection forms the rigid substrate. After the substrate forms, another shot (generally thinner and more pliable) is injected in, on, or around the substrate. As the materials cool, they bond together, creating a unified, strong, and durable part. Bonds can be chemical or mechanical, depending on the materials as well as the design of the part or product.

2-Shot Molding

What is two-shot molding? Two-shot, also referred to as dual-shot, double-shot, multi-shot, and over-molding, is a plastic molding process in which two different plastic resins are molded together in a single machining cycle, allowing engineers to create multi-material or multi-colored parts without adding extra assembly steps.

This is a personal favorite! Maybe it’s the movement or complexity? Either way, it’s pretty fancy processing! Take a look:

https://youtube.com/clip/UgkxcBcKlFILmSEin82fxXSvS3QUqJT5KIGP?si=_4HGYnGbxX2dtt0a

Vertical Molding

I recall seeing a vertical mold running for the first time…do you? It’s memorable! The major difference between the two options is the vertical mold operates perpendicular to the floor surface, and moves up and down rather than side to side. And why would you ever need to choose a vertical mold instead of a horizontal one?

Your parts require insertion or over-molding to enhance the product function and/or visual appeal. Inserts used for insert molding will be held in place by gravity, which makes the operation easier to incorporate.

Your operation requires a smaller injection molding machine that takes up less floor space.

Review the full scope of vertical molding attributes at Sea-lect Plastics.

If you want to learn more about the ins and outs and the verticals and horizontals of the plastic world, we suggest you view our trade show list below and plan to attend one!

Contact Fast Heat by Spark Industries…we can help with your injection molding needs!

Automate Chicago 2024

May 6-9, 2024

The biggest automation show. The best solutions. 365k+ square feet! 800+exhibitors!

Plastic Minneapolis 2024

Oct. 16 – 17, 2024

Plastics processing resources for manufacturers in Aerospace/aviation, Appliances / Housewares, automotive, electronics, medical, packaging, consumer goods, and more.

NPE: The Plastics Show 2024

6-10 May 2024

The largest plastics trade show in the Americas, NPE, provides a platform for technology and ingenuity to advance product innovation. It brings together experts in various fields to transform the industry.

Plastics Extrusion World Expo 2024

18 – 20 Mar 2025

This international exhibition brings together professionals from across the plastics extrusion industry for two days of networking, knowledge sharing, and innovation in Cleveland.

Plastics Technology Expo

10 – 12 Jun 2025

PTXPO is your hands-on opportunity to see and feel the newest plastics machinery, immerse yourself in free educational sessions, experience equipment demonstrations, and participate in numerous networking opportunities.

References:

Hot Runner Injection Molding Process

Hot Runner Maintenance Guide

Common Hot Runner Cable Connection Problems

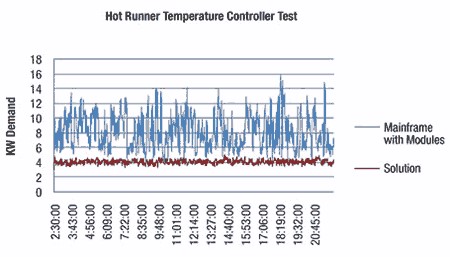

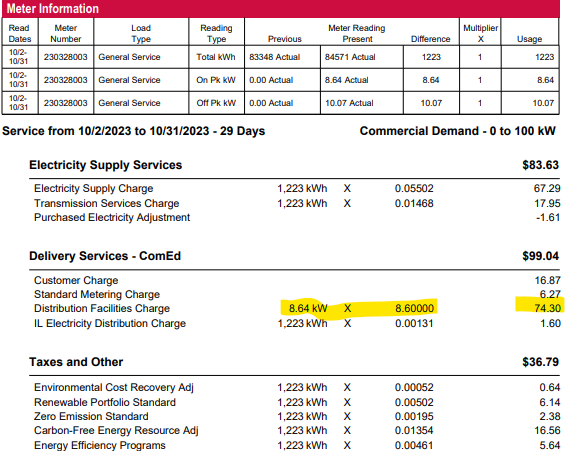

Hot Runner kW Demand