We have established injection molding best practices for processing with hot runner systems as outlined in this post. Our particular area of expertise is hot runner temperature control. This is supported by decades of hot runner system design and implementation as well.

We address the essentials of hot runner system processing including:

- What Melt Flow Index really means

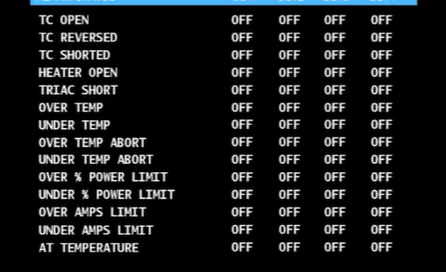

- Properly reading and responding to thermocouples

- The four plastic variables

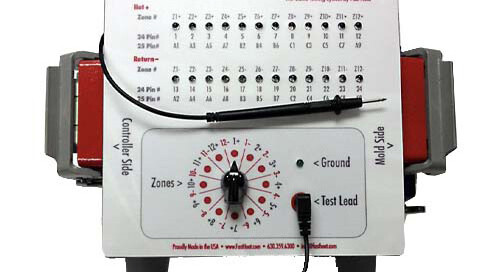

- Hot runner temperature control

- The other “part-to-print” variables

Here’s what people have to say about our hot runner controls:

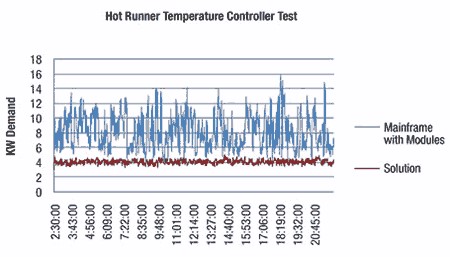

We’re Reliable…

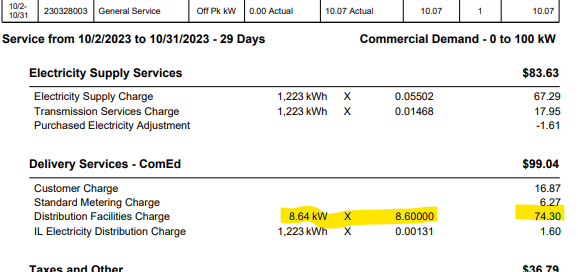

“We knew we needed an integrated controller but were concerned about the higher purchase price over our modular box units. The Pulse Controller fit our needs because it was affordable and offered advanced technological features that save us time and money. Our personnel have all commented on how easy they are to use and that they are reliable.”

“I prepared a very detailed product comparison between the Pulse and another leading integrated controller. We decided to buy the Pulse because it met our technical requirements and was easier to use. Fast Heat also supplied a trial unit in much less time.”

We’re Precise…