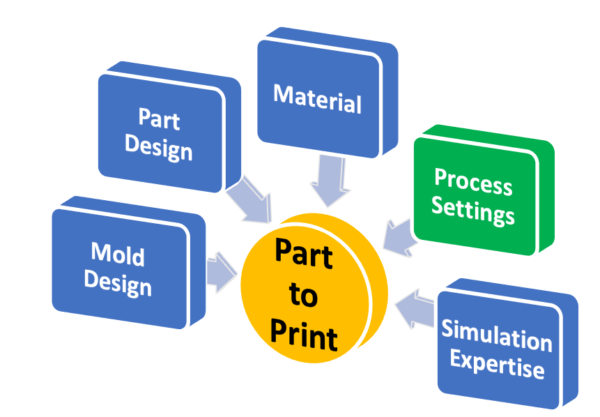

Helping molders simplify their injection molding process is the central theme to our industry-unique solutions including hot runner temperature control, heated sprue bushings, heated machine nozzles, screw tip assemblies, and custom injection molding screws.

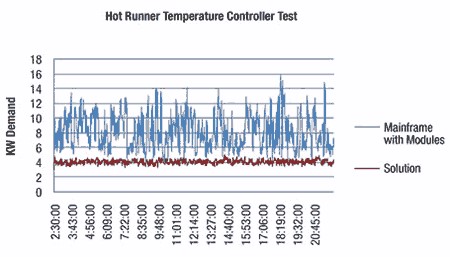

Hot runner control optimization stabilizes your process by minimizing the amount of over and under shooting of temperature. This opens processing windows, maximizes uptime, reduces scrap and enables more advanced manufacturing practices.

Heated sprue bushings with integrated heaters offer superior heat transfer for a wide range of resins. The streamlined flow channel terminates in a reverse taper gate, providing minimum pressure loss and allowing for rapid gate freeze. The formation of a small gate stub on the part or runner results in a machine hold-time reduction, with no increase in sink marks on the part.

Our heated machine nozzles feature swedged sleeve heaters for optimal heat profile, durability, and replaceability. The core nozzle can be optimized for flow, wear resistance, or corrosion resistance.

4-piece screw tip assemblies not only save on maintenance costs but can also be optimized for flow, wear resistance, or corrosion resistance.

Finally, our Zeiger customized screws are as true to center as you will find in the industry and can be optimized for melt residence time as well as corrosion and wear resistance.

Each of these solutions help to improve the injection molding process.

We also have industry partners available to assist with mold flow analysis, injection molding process training, and problem resolution. These include CAE Services, RJG, American Injection Molding Institute and more.