Injection molding best practices related to Fast Heat by Spark Industries hot runner controls, diagnostics and related products and services.

Our Productivity Series is designed for high-cavity injection molders and follows a normal sequence of events on the production floor:

- kW Demand Planning

- Maintenance

- Troubleshooting

- Processing

- Molding Cell Integration

Some excerpts from this category of best practices includes:

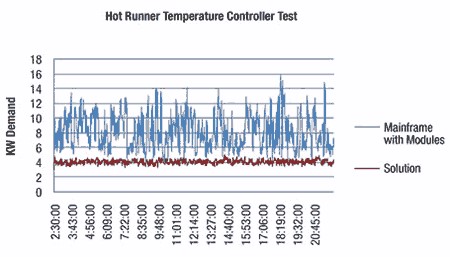

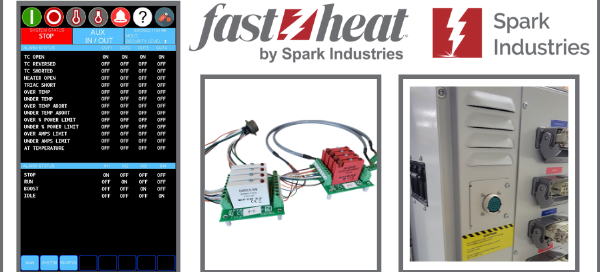

High-cavity hot runner systems can consume a lot of electricity. When you register for this productivity series, we’ll send you an Excel spreadsheet to calculate the total system amps for your tools. For example, a recent customer figured that the total system amps for their 72-zone hot runner system is 359.7 amps! We’ll show you how our Pulse hot runner controllers enable you to minimize start-up kW demand and automatically limit peak amp draw by up to 67% while maintaining precise temperature control during set-point operation.

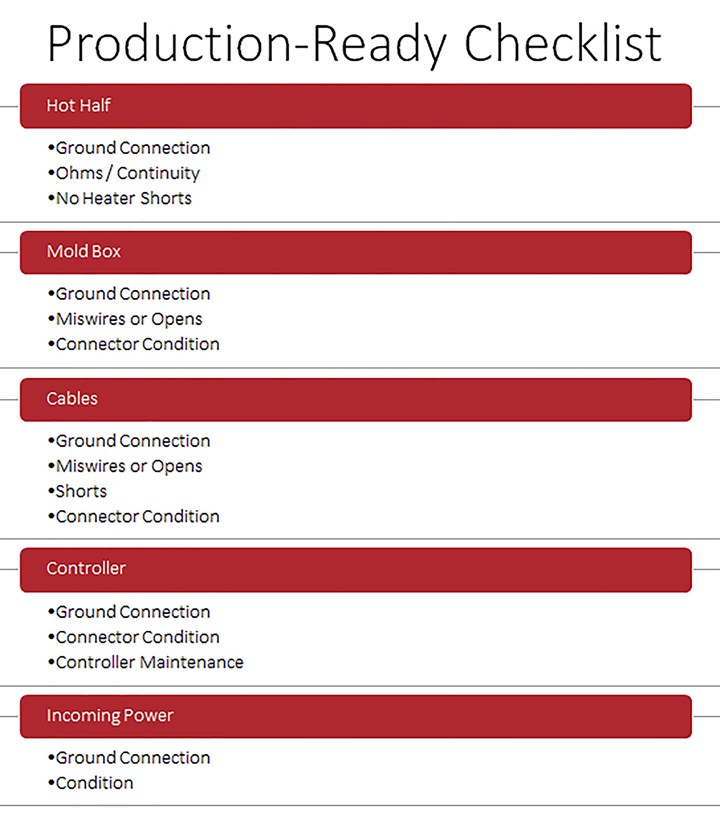

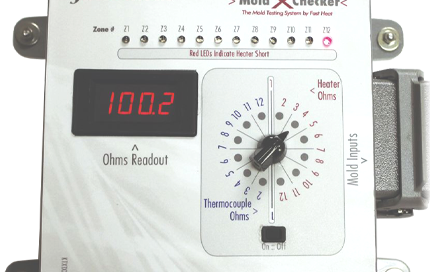

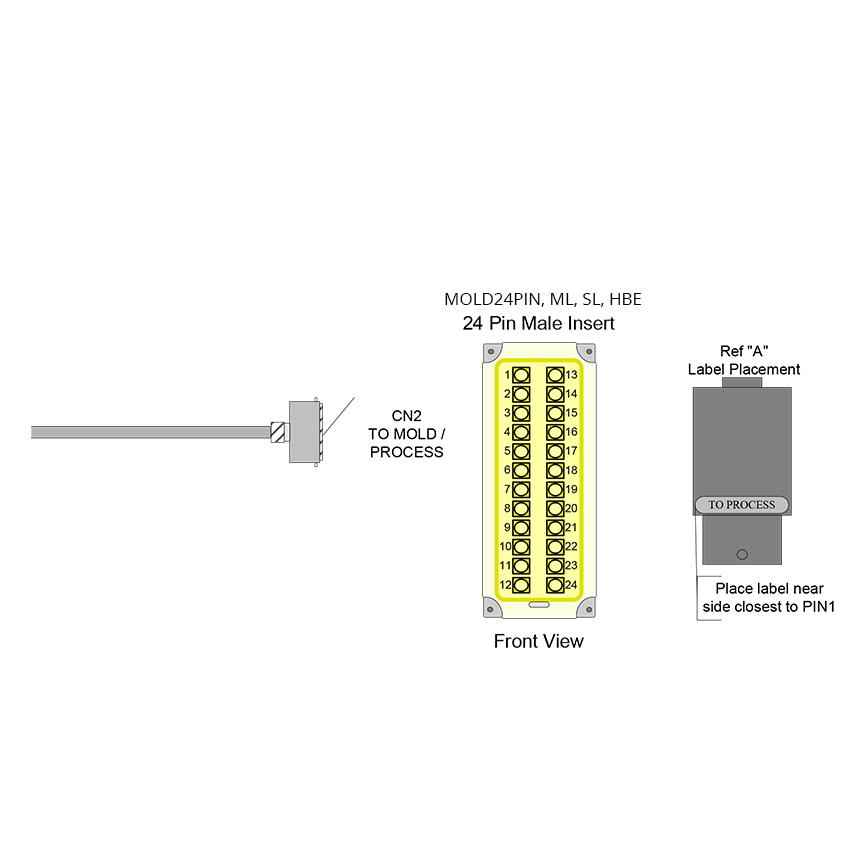

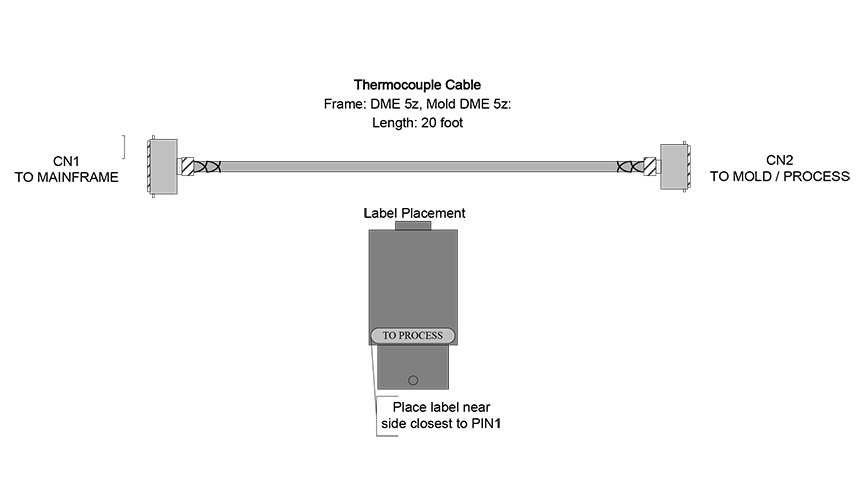

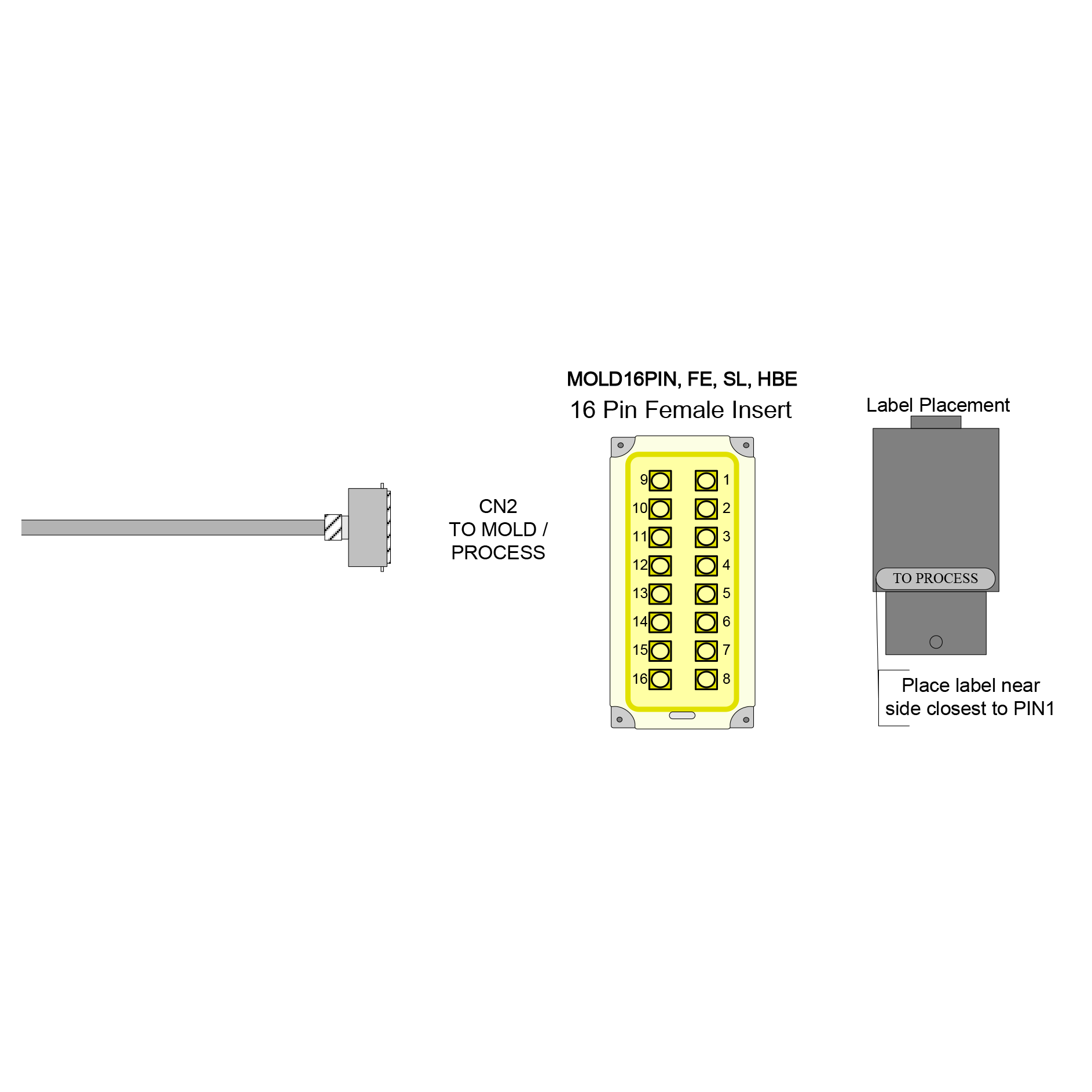

Maintaining hot runner systems and cables can be a tedious job. We’ll send you a training guide to show you how to use our MoldXChecker™ and CableXChecker™ to save you time and ensure 100% accurate system and cable testing results. And, whether or not you use our tools, this guide will help show you how important it is to check for opens, miswires, and dangerous shorts.

References:

https://fastheatbyspark.com/hot-runner-injection-molding-process/

https://fastheatbyspark.com/hot-runner-kw-demand/

https://fastheatbyspark.com/about/